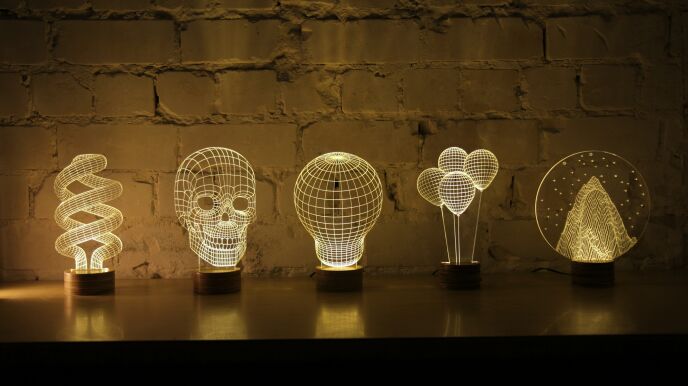

Stained glass is one of the main attractions at many of the world’s famous churches. An Israeli company has decided to take this colorful craft to the next level. It’s called Dip-Tech, and thanks to its innovative digital glass printing solution, ordinary-looking buildings are turned into extraordinary landmarks.

Printing on glass is not groundbreaking. But printing on glass with durable ceramic inks by digitally transferring images onto the panes of glass is revolutionary.

Spread the Word

• Email this article to friends or colleagues

• Share this article on Facebook or Twitter

• Write about and link to this article on your blog

• Local relevancy? Send this article to your local press

Since kicking off business in 2005 in the town of Kfar Saba, just outside of Tel Aviv, the company’s unique solution has converted hospitals, shopping centers, museums, office buildings and universities around the world into pieces of art.

In Australia, there’s the new Munday Wall, an enormous eight-by-nine-meter mural featuring an indigenous painting reproduced onto glass.

The Harlem Hospital in New York is another great example, with its full-color building façade made of glass panels in the colors and styles of 1930s Harlem art and culture.

The façade of the Carmel Academic Center in Haifa, boasts colorful and lively portraits of well-known Israeli culture personalities on its building exterior.

CEO Yariv Matzliach sees Dip-Tech as part of Benny Landa’s digital printing revolution.

“He did it for the digital press; we’re doing it for glass,” Matzliach tells ISRAEL21c. “Dip-Tech’s niche is to digitalize the world of glass.

Our printers are installed and working all over the world. The combination between traditional industry and the end product is a piece of art, and that’s what gives us the joy of being part of the digital revolution.”

Israeli-made, globally printed

Headquartered in Israel, Dip-Tech has sales offices in the United States, China, and Europe. From 2010 to today, the company has shown a growth rate of 30-50 percent. Matzliach says sales this year are expected to reach some $30 million.

- Artist Alexander Beleschenko won a competition with this multi-colored printed glass design for the Forum, University of Exeter, UK. Dip-Tech digital in-glass printing with ceramic inks was the only solution capable of meeting the challenges posed by so many colors integrated in an external application.

Dip-Tech creates the innovative technology and then sells its system of image processing software, ceramic inks and digital printers to glass fabricators around the world.

“We have patented our technology with the Hebrew University of Jerusalem to develop patented ceramic inks. We have patented our printers as well. We have very strong IP,” Matzliach claims. “I have a lot of faith that our technology is the leading technology.”

The first step in the process is for designers and architects to come up with an image they’d like to see on a building. For example, Ventrano architects conceived the idea of a forest mural for the AFIMALL shopping complex in Moscow.

They then used Dip-Tech’s image-processing software — a special graphics program that turns standard graphic files into ready-to-print images that are tuned for optimum results on glass. This process is unique to digital printing and could never have been completed with traditional methods such as screenprinting.

The next step is choosing colors. Unlike UV printing, Dip-Tech’s ceramic, all-weather digital inks fuse into the glass, explains Matzliach. And that protects them from ever fading. The printed design will stay as long as the glass does.

The AFIMALL exterior shows a photorealistic design of a typical Russian forest, digitally printed in-glass on 2,650 panes. Additional glass elements jut out from the building and the image seems to create an impression of depth to the forest.

“Digital printing is a tool that makes it possible to incorporate and express ideas that until now were left on paper,” said architects Jesús Zafra and Javier Alarcón, who built a landmark office building in Spain.

Printed glass functionality

Matzliach says Dip-Tech’s digital ceramic inks, when printed on glass, support multiple sustainability functions, including energy efficiency, solar/light control, light diffusion and transmission, and glare reduction; urban renewal and building preservation; electrical conductivity; and use of low-impact materials.

Dip-Tech’s solution for glass also can be used for super constructions, backsplashes and interior elements.

The company has created an anti-collision glass application that could save the lives of millions of birds around the world. “We have a special feature where a bird can see the glass from a distance thanks to the printed pattern,” he says.

Dip-Tech has also developed a slip-resistant ink for flooring and roofing, suitable for home and commercial applications.

Currently, Dip-Tech is working on bulletproof glass for armored cars, specialty transportation glass for windows of trains, buses and airplanes, and even cost-effective printing solutions to replace glass windows of cars.