Leading three-dimensional printer manufacturer Stratasys, dual headquartered in Minneapolis and Rehovot, Israel, made a 3D printer large enough to print out a full-size prototype of a futuristic electric car called the StreetScooter.

Using extruded plastic to make actual devices and prototypes of devices under design is nothing new in the rapidly growing 3D printing space, as ISRAEL21c has reported.

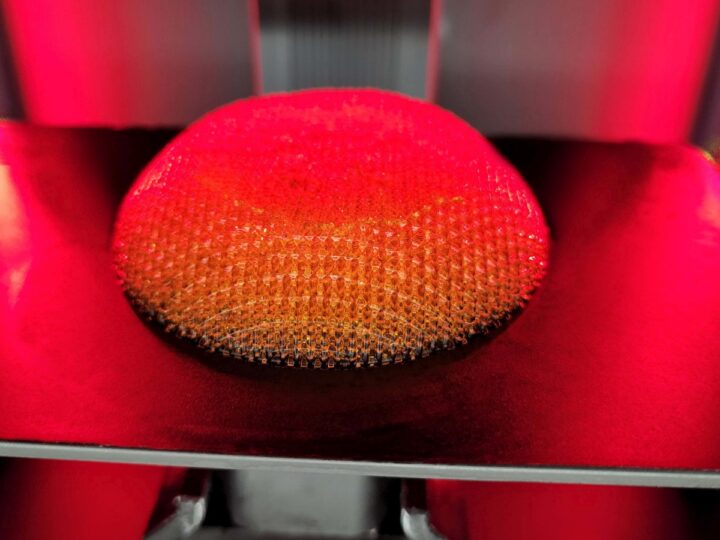

However, the made-in-Israel Objet1000 3D Production System heralds a milestone for its sheer size. Its build tray is the largest in the world at 39.3 by 31.4 by 19.5 inches. This gives designers and investors the ability to visualize and test a 1:1 scale model of tomorrow’s engineering advances.

The StreetScooter was developed at Aachen University in Germany to rival conventional vehicles on price with performance, safety and sustainability. The basic city car is expected to weigh 450 kilograms (1,000 pounds) excluding the battery, with a range of 100 kilometers (80 miles) per charge.

The Objet1000 Multi-material 3D Production System was used to print models for all of the StreetScooter’s exterior plastic parts, including the large front and back panels, door panels, bumper systems, side skirts, wheel arches, lamp masks, and a few interior components such as the retainer instrument board and a host of smaller parts.

The printing material is a durable digital ABS plastic, so that the prototype car can be put through strenuous testing environments at the same level as a vehicle made of traditionally manufactured parts.

https://www.youtube.com/watch?v=wfpJLkX9m7I

“The Objet1000 is the largest multi-material 3D production system on the market and Aachen University was the first university in the world to have one,” said Prof. Achim Kampker of the faculty of mechanical engineering.

“Being able to use it in the development of large and small parts for StreetScooter was exciting in itself, but the contribution the 3D printed parts made to the construction of the car was enormous. The ability to produce full-scale prototypes that perform like the final parts, accelerated testing and design verification, enabling us to bring to market a prototype electric car in just 12 months — something that is just unimaginable with traditional manufacturing.”

Stratasys is one of 80 companies working with the StreetScooter company, founded in 2010 by university professors and German automotive suppliers.

Kampker added that this 3D printing technology will allow vehicles to be customized easily for specific customers. “These cars can be developed from scratch and ready in a matter of months, not years, as with traditional automotive production processes. The StreetScooter project has demonstrated to us how a whole new approach to car design and manufacturing is possible with 3D printing.”

Thanks to Israeli environmental blog Green Prophet for alerting us to this development.