Lab-grown (cultivated) meat has captivated both food and climate scientists with the tantalizing prospect of reducing animal suffering along with methane output from farm animals that contributes to climate change.

The same technology, it turns out, can be used to grow plant molecules in a lab.

Why would you want to do this?

First, plants suffer the effects of climate change. A prolonged drought, pollution, fire or severe winter storms could ruin an entire year’s crop. Pests and diseases can wipe out whole species of fruits and vegetables. Supply chain problems have stoked increased food insecurity in many parts of the world.

Furthermore, some plants have medicinal properties that can be more easily isolated and produced in a lab.

The bark of the yew tree, for example, is the basis for two chemotherapy drugs – docetaxel and paclitaxel – used to treat breast and ovarian cancer.

Another example: saffron, the most expensive spice in the world due to its highly labor-intensive process of separating the saffron stigma from the crocus flower. One kilogram of high-grade saffron requires up to 150,000 flowers. That takes up vast amounts of land – half of it in Iran – which also contributes to the price inflation.

Affordable saffron could be used in all manner of products, from cosmetics to nutraceuticals, for its anti-inflammatory, anti-aging, anti-wrinkle and antioxidant properties.

ReaGenics, an Israeli startup, is leading this lab-grown plant revolution.

Harvesting molecules

“We don’t create full plants in our bioreactors,” ReaGenics CEO Michael Kagan, tells ISRAEL21c.

“Rather, we are harvesting molecules, which can be mass produced inside our lab without requiring large swaths of land and resources. ReaGenics grows the essence of the plant. You don’t end up eating a little carrot.”

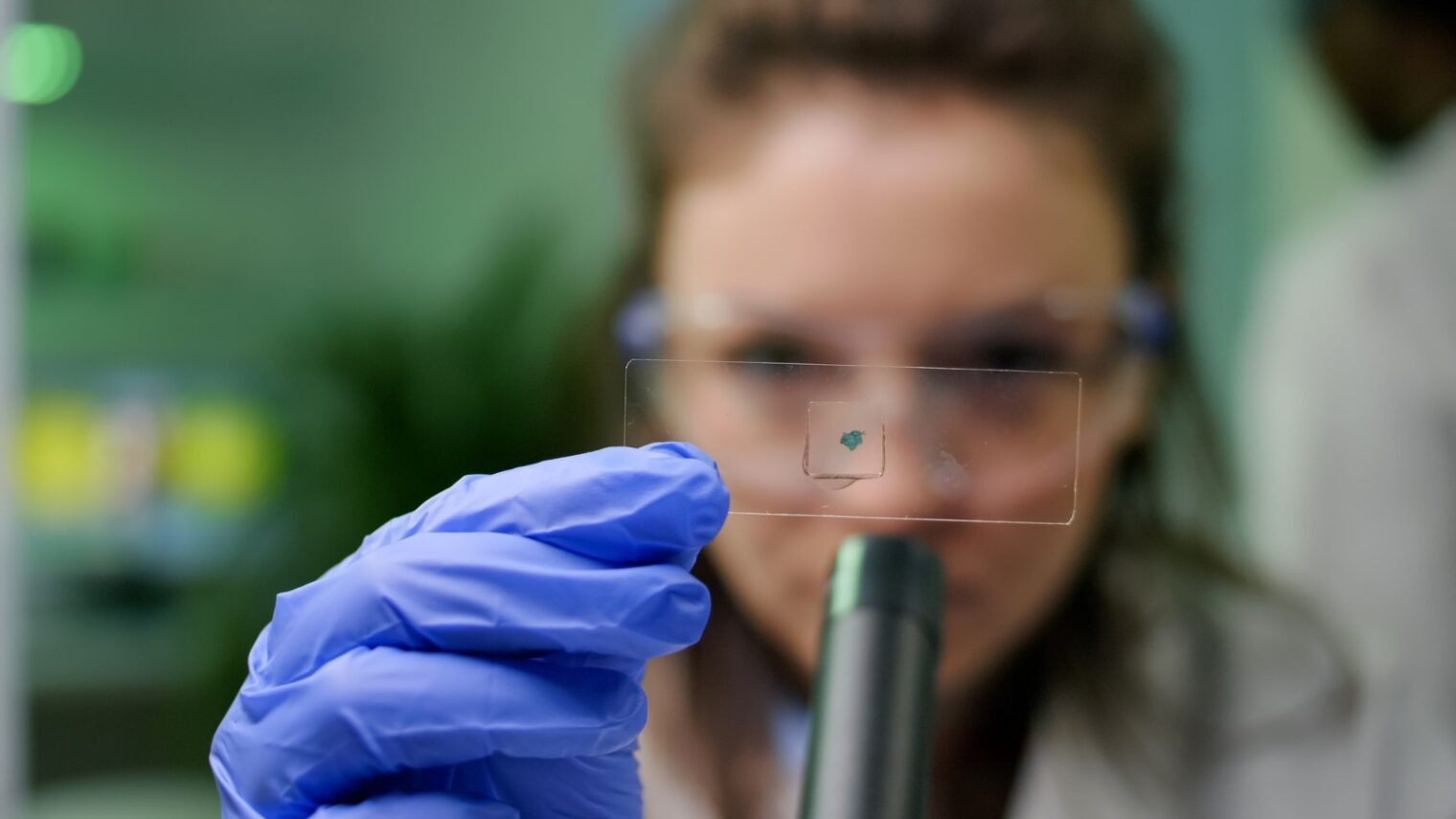

The process starts with stem cells, Kagan explains.

“A cutting of differentiated cells – these are cells that have already become a leaf, a stalk or bud, a fruit or even a root – is taken from a living plant, decontaminated in the laboratory, and placed in petri dishes. Instead of regenerating into a new plant, the cells are forced to revert to stem cells – that is, cells that are undifferentiated.”

Kagan likens it to military recruits who all do the same basic training before getting assigned to

infantry or tanks or other units.

Once ReaGenics has the stem cells, they are put into a bioreactor, “which allows us to continuously harvest them,” Kagan says.

“The amazing thing about these stem cells is that they are all viable, meaning that when they’re placed in liquid media, they reproduce like bacteria.”

The stem cells are joined in the bioreactor (really just a flask) by minerals, growth promoters and sugar. Continuous gentle stirring prevents the stem cells from aggregating into a plant.

In the case of saffron, Kagan adds, “We can use the dried stem cells as a product – a novel form of saffron – or we can extract out the active, potent molecules inside the cells, such as crocin and safranal.”

Once they have reached a high enough concentration in the flasks, “the cells are transferred to bioreactors of increasing volume until they reach the industrial scale of 1,000 liters,” Kagan explains.

Magic mushrooms

What else can ReaGenics grow?

Cannabis and psilocybin (magic mushrooms) are high on the company’s list. In fact, ReaGenics started in 2019 with a focus on cannabis to treat inflammatory bowel disease.

“The problem with cannabis,” Kagan explains, “is that there are 140 different cannabinoids – the molecules that the cannabis plant produces. That includes THC, CBD, CBG, CBN and more. They’re most effective when they work synergistically. But it’s not easy to get consistent formulations of the exact combination of cannabinoids when the plants are grown outdoors in a field or indoors with artificial lighting.”

ReaGenics can generate the precise molecules needed to ensure cannabis consistency.

“If you made an isolate of just THC,” Kagan continues, “you wouldn’t have the problem with consistency, but then you don’t get the ‘entourage effect.’ For that, you need a technology that can create a consistent ratio between them.”

That might be possible when you have one, maybe two molecules to control. “But when you get to four or five, it’s an impossible situation.”

The same is true with mushrooms, where there are several hundred different species of fungi, many of which can be considered “magic.” A ReaGenics bioreactor can grow psilocybin molecules with consistent potency.

Chemical-free

Lab-grown plant molecules also avoid issues with pesticides and chemical herbicides.

“There are over 100 different pests that attack cannabis plants, with new ones being discovered all the time,” Kagan says.

When grown in a lab from stem cells, no pesticides are required, bacteria and viruses that coexist with the plant are eradicated, and harmful pests can’t find their way in.

“In the past, food insecurity was due to overharvesting pieces of land. You could let the land lay fallow and the soil would replenish itself,” Kagan explains.

“Today, we’re in a very different situation. The soil has become overused. So, it needs more and more fertilizer. Moreover, shifts in temperature are causing plants that grew comfortably in the past to be not so comfortable anymore. ReaGenics provides an alternative way to grow plant matter.”

Highly scalable

ReaGenics’ key competitor, the Israeli company Protalix Biotherapeutics, has 300 bioreactors in the north of Israel growing animal proteins inside plants. The company’s genetically altered carrot stem cells led to a treatment for Gaucher disease distributed by Pfizer.

Kagan says that ReaGenics has distinguishing aspects such as a highly scalable bioreactor system made from long-lasting stainless steel, and an automated harvesting process that reduces the need for human labor.

ReaGenics’ production facility in Israel will be a showcase with 60 bioreactors in the first stage, going up to 200. The company aims to sell or license the means of production to interested parties.

“To build a giant production facility to provide plant protein on a scale that’s more than a tiny drop in the bucket needs massive infrastructure. So, partners will be responsible for building the plant and we’ll supply the cells under license,” Kagan says.

That’s already happening in Malta where the government has granted ReaGenics 1 million euros, with a Canadian cannabis company putting in the rest. The goal is to build 500 bioreactors in Europe to produce medical cannabis for customers there, and another 3,000 bioreactors in Canada.

Kagan is a classic high-tech Renaissance man. Trained as a chemist, he’s worked in producing Omega-3 from algae, location-based digital communications software, and solar-thermal energy. He’s also written books and plays, and produced documentaries.

ReaGenics has raised $3.3 million and employs 12 in the Tel Aviv suburb of Ness Tziona. Kagan hopes that by Q2 of 2023, the company will have “a set of full-scale bioreactors producing material.”

For more on ReaGenics, click here.