An Israeli startup that suffered damage from the war is picking up the pieces to quite literally construct a better, greener world, turning an eco-friendly plant grown in one of the communities on the Gaza border into sustainable building materials.

Kenaf Ventures specializes in turning the kenaf plant (Hibiscus cannabinus), known for its carbon dioxide absorbing properties, into biomaterials that can be used by various manufacturers. This both cuts down on CO2 levels and reduces polluting raw materials in industries such as construction, insulation and plastics.

The startup, established in 2018, is headquartered in Tel Aviv but has most of its operations based in Kibbutz Kfar Aza, one of the communities that was hardest hit in the October 7 Hamas massacre, with 58 people murdered and 17 kidnapped.

Production at a newly launched factory in the kibbutz was interrupted, and the company is raising money to continue operations after many of its colleagues and investors were severely affected by the attack.

‘We will continue’

“We mourn the tragic, untimely passing of many of our partners – a rare mosaic of precious individuals who have long since become family,” said Kenaf Ventures President and CTO Avishay Morag, who founded the company with Gideon Soesan, Asaf Ofer, Aviv Spiner and Ido Hershkovits.

“In the two days preceding the disaster, we were still making plans in the pastoral tranquility of the kibbutz regarding the global novelty that would reduce air pollution and encourage the transition from the use of polluting raw materials in the industry to those with a negative carbon footprint,” said Morag.

“It is still too early to assess the scale of the tragic events still occurring. Nevertheless, one thing is clear – we will continue our life’s work, which is forged in a courageous partnership with the residents of the Hatkuma [Resurrection] Region,” they added, referring to the new name of the area formerly referred to as the Gaza envelope.

A versatile plant

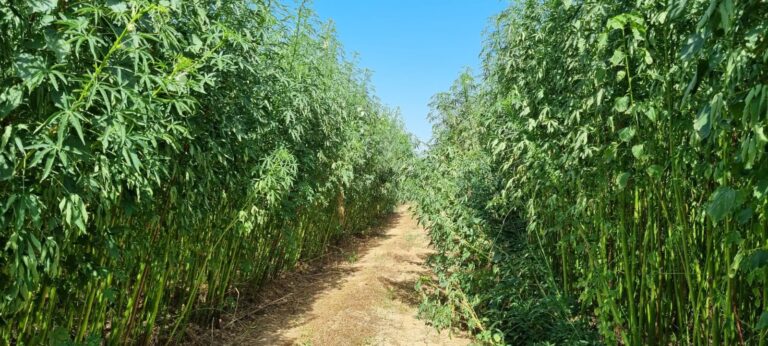

Alongside the factory established in Kfar Aza, Kenaf Ventures also had extensive kenaf fields in the surrounding area.

Originating in Africa, kenaf is versatile and can be grown in different soil types and climate conditions, requiring minimal water. It can absorb large amounts of CO2, heavy metals from the soil and even heavy oils like tar.

Fibers similar to jute are produced from the plant, and can be used to produce absorbents, fabrics, packaging materials and oil, as well as building materials.

In the field of construction, for example, Kenaf Ventures has developed sustainable solutions such as blocks and plaster with improved thermal and acoustic insulation, strength and fire resistance, all based on kenaf’s unique properties.

In the plastics industry, the company uses kenaf as a substitute for petroleum-based plastics such as polypropylene, resulting in a bioplastic compound with significant percentages of organic matter as a plastic substitute.

“From the very beginning, it was clear to us that our developments to promote decarbonization in the industry must be those that will create a real impact at a competitive price and on a significant scale,” said Soesan, the company’s head of new growth.

“Extreme climate events are accelerating the pace of global regulation, and global markets need to adopt sustainable solutions immediately, so that our infrastructure is ready to penetrate markets such as the United States, Europe and Asia.”

Not discouraged

Asaf Ofer, the CEO of Kenaf Ventures, said the company “will not allow anyone to discourage us.”

“Unfortunately, this disaster damaged the body, soul, and finances of many of our company’s partners, employees, and strategic investors, requiring us to generate a subsequent round of financing,” Ofer said.

Their goal is “not only to rise and restore a sense of normalcy, but to continue the path we paved to combat carbon emissions and reduce the damage caused by over-industrialization around the world with an accessible, cost-effective, easy, and quick solution to implement on existing systems.”

Morag predicts that the products will help manufacturers become more profitable.

“In addition to the associated social and environmental value, manufacturers will be fined less for environmental damage and enjoy an improved public image, which will inevitably affect performance in the short and long term.”

Finally, he added, “We are determined to spread the word that will help humanity reduce hundreds of millions of tons of CO2 and other pollutants from the environment.”

For more information, click here.