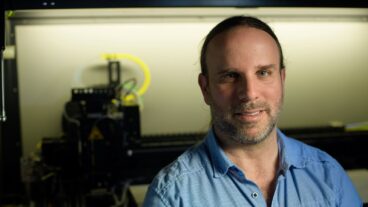

Udi Shamai knows pizza.

The owner of the Pizza Hut master franchise in Israel since 2008, with a stint at Domino’s before that, Shamai has a reputation for combining dough and cheese with software and hardware to help make that pizza taste even better – and to get it to your door with a minimum of human involvement.

Shamai is now digging deep into the dish with his latest startup, Hyper Food Robotics, which creates modular, portable robotic pizza kitchens.

Robots in the kitchen? What was wrong with the old-fashioned way of preparing a pie? Shamai tells ISRAEL21c there are three problems.

First and foremost is cost. Staff comprises some 20% of the costs of running a pizza chain. Robots, on the other hand, never get sick and never need vacations or cigarette breaks. Replacing humans with robots will save Pizza Hut money. (Whether the retailer will pass that savings on to the consumer is another matter entirely.)

Second is safety: Robots don’t make mistakes. They don’t use ingredients that have passed their expiration dates and they never forget to wear their protective gloves while getting down and dirty with the dough. A self-contained “plug and play” robotic system can even monitor the air quality, so everything stays hygienic.

Finally, there’s consistency. A human worker may make a great pizza at the beginning of his or her shift, but after eight hours, a customer might get a sub-optimal pie.

Hyper’s solution is a 40-foot container fitted with easily configurable robots that can prepare the dough, sprinkle the cheese, toss on toppings and put the pie in the oven before transferring it to a warming box, sliced and ready for delivery.

A pizza pro

In October, Singapore-based travel and hospitality venture capital firm Velocity Ventures invested in Hyper, which is expected to launch its first fully robotic pizza kitchens in 2023.

Hyper is focused on the US market, Shamai notes, but the Velocity investment should accelerate Hyper’s adoption in Southeast Asia.

Hyper is not Shamai’s first food-related startup. In 2014, he founded DragonTail, a software system for optimizing the running of a fast-food restaurant. Precisely tracking orders and deliveries, which seems so obvious in the age of DoorDash, GrubHub and Wolt, simply didn’t exist then.

DragonTail was acquired by Yum! Brands, the parent company of Pizza Hut, Taco Bell and KFC, and now Dragontail’s order management and delivery technology is incorporated into 1,500 Pizza Hut restaurants across about a dozen countries.

From dough to cleanup

When Shamai started Hyper, he initially hoped to assemble the robotic kitchen from off-the-shelf parts, but quickly realized that all the machines had to be proprietary.

Hyper cofounder and COO Yariv Reches engineered the system from scratch.

The robots can make 120 pizzas an hour, about three times more than in a typical human-staffed kitchen. They use a patented method for stretching and rotating the dough, and specially designed dispensers that pour exact amounts to avoid waste and uneven distribution.

The robot’s arms work with special conveyers to get the product from one station to the next.

“The robots move the pizza into the oven, take it out, cut the slices and put it in the box to be stored in a delivery cabinet,” Reches continues.

“The delivery person finds what he’s looking for and can take drinks and salads out of the same cabinet.”

Hyper’s robots even take care of the cleanup. In the future, Reches notes, they could be programmed to do even more.

Although Hyper is not alone trying to automate fast-food operations, Shamai says that “no one else is doing a full concept store. Some will just retrofit an existing store.”

He adds that whereas a conventional pizza shop generates about 14% profit, Hyper can push that profit margin to 34%.

Ghost kitchens

Now, don’t expect to walk into a next-generation Pizza Hut and see robots working in the back room.

Hyper is hyper-focused on the “ghost kitchen,” a separate delivery-only location that’s often located in a less-trafficked, industrial part of town, Reches tells ISRAEL21c.

“When you order a pizza, you don’t care how it’s made, just that it comes on time, it’s warm and tasty and safe to eat. We are ghosting the ghost kitchen.”

Shamai goes one step further.

“In a couple of years, there won’t be one person working in the fast-food delivery business,” he claims.

This also fits with Velocity’s investment philosophy. Velocity was established just as Covid-19 started.

“They wanted to find solutions to cope with this new world,” Reches says. “There was no one available to work during Covid but everyone wanted to order pizza. They saw an opportunity – not just because of Covid. It also fits the problems and the pain this sector had.”

A fully robotic kitchen can even track supplies, “so we always know when to order new tomato sauce or pepperoni,” Reches says.

Pilots now, bowls later

Hyper has been piloting its robotic kitchen in Israel with Pizza Hut and Yum! since 2021, and Shamai expects to robotize 10 existing Israeli pizza kitchens in 2025.

Meanwhile, the company is starting trials with ghost kitchens in the United States and Asia. All that’s required is to hook up the container to electricity, water and sewage.

Pizza Hut is on board, naturally, but Shamai emphasizes that “the process is the same whether it’s Pizza Hut or Domino’s. The difference is the dough, the side dishes and the specific ingredients,” Shamai says. In high tech lingo, that means Hyper is brand agnostic.

Hyper will charge both a one-time setup fee and a percentage of sales. The stores’ operations can be remote-controlled from a central location.

Hyper’s 15 employees, based in Petah Tikva, are working on the next development:

Robotically prepared “bowl food” (stir fries, poke bowls, all kinds of Asian fast-food options), followed by burgers.

“Sixty percent of the functions we developed for pizza will move forward to the next type of store – even salad, ice cream or Mexican food,” Reches notes.

For more on Hyper Food Robotics, click here.