Halogen is too hot, fluorescent too harsh, incandescent so inefficient it’s being phased out in many countries. The lighting technologies of today are cool, economical, long-lasting and ecological.

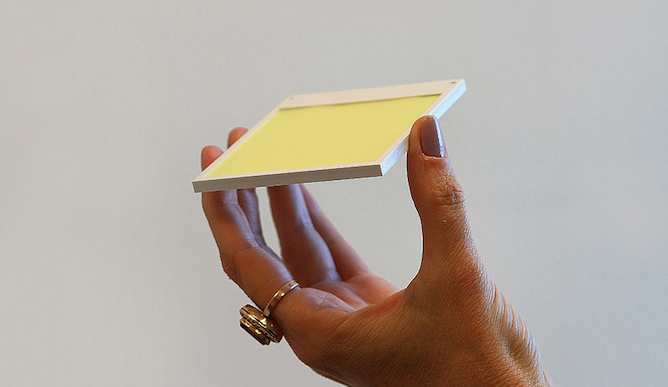

In a field crowded with seekers of the ultimate disruptive lighting tech, the spotlight is on Israeli company Oree Advanced Illumination Solutions for its LightCell — a thin, flat panel spread uniformly with powerful LED (light-emitting diode) light. LEDs are commonly used as point light sources rather than as thin panels.

Available in three basic sizes – solo, duo and quad – Oree’s futuristic improvement on the light bulb uses less energy and takes up less space while delivering more lumens per watt and superior light quality. The five-watt solo module gives off as much light as a 40-watt standard bulb.

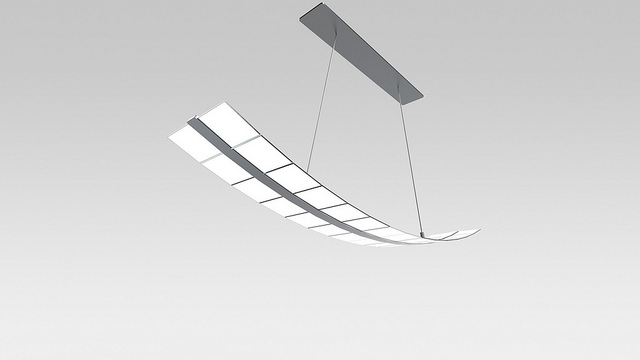

“What’s unique is how thin it is — just four millimeters — and the unusually high lumens per watt,” says Chief Financial Officer Amir Steklov, showing ISRAEL21c LightCells installed in a prototype fixture hanging in a conference room at Oree’s two-floor R&D headquarters in Ramat Gan.

By coincidence, or maybe it’s a matter of destiny, the office building in which the company rents space is called Beit Or (House of Light).

Unique uniformity and thinness

Oree (Hebrew for “my light”) became a glimmer in the eye of Israeli television producer and serial inventor Eran Fine when he was sitting in the dentist’s chair and thinking how to improve on the large overhead light.

His first thought was to make a glove with a lighting source in the fingertips, but that wouldn’t be practical since dentists’ gloves must be disposable. So he began rethinking how light is produced, and teamed up with engineer Noam Meir to establish Oree in 2006. They attracted funding from a veritable United Nations of investors: Genesis Partners in Israel, Gimv in Belgium, FGC in Japan and Epistar in Taiwan.

The pair decided to improve on LED technology – the current industry standard — by embedding Epistar chips into a light guide so the diodes spread light uniformly across the planar (two-dimensional) surface.

Their invention is protected by patents in the United States, Europe and China, and meets the goals of modern lighting technology, where the buzz words are thinness, energy efficiency, low cost and uniformity. Hitting all these targets is easier said than done.

For example, a prototype 200 lumens-per-watt LED fluorescent tube unveiled last April by international corporate giant Philips lacks the thin profile. Samsung and other companies are investing heavily in OLED, a thin one-layered organic LED product, but it’s expensive. Edge-lit LED backlighting, used in today’s slim televisions, don’t deliver uniform light.

“A lot of companies can bring the thinness or the uniformity or the higher lumens per watt, but we are the only company in the world that can bring it all together in one package,” says Steklov.

Former Philips Lighting CEO Peter van Strijp of the Netherlands joined Oree as chief executive in 2012, when Oree was ready to shift from R&D to sales.

On the market since August 2012, and made in Thailand at a rate of up to 100,000 units per month, LightCells are already a hot-ticket item with lamp manufacturers in Europe and Asia. Companies in the Netherlands, Turkey, China, Japan, Korea and India have been snapping up the panels like hotcakes.

Under cabinets, inside the fridge

And Oree is just getting started, introducing the portfolio of LightCell products at trade shows around the world. The possibilities for this little invention seem infinite.

“Our expanded range of planar lighting modules will enable designers and fixture manufacturers to innovate and create new form factors that previously were unimaginable,” predicted van Strijp.

LightCell modules can be integrated into suspended fixtures, desk lamps, task lighting and decorative lighting. Several hotels have built them into corridors. A refrigerator manufacturer plans to use them to illuminate shelves, and IKEA may install the Israeli product on the undersides of cabinets.

“You can even glue it to wood, because it does not get warm,” says Steklov.

The LightCell comes in color “temperatures” from cool white to warm white (depending on the phosphorus coating), and lasts 50,000 hours. The panel can be dimmed and controlled by computer. Connectors and drivers are also available to make the LightCell a full plug-and-play system for fixture manufacturers.

Aside from sales staff deployed globally, most of Oree’s employees in Ramat Gan are veterans of the electro-optics, software and physics fields. “We are now looking to open a separate office in China,” Steklov tells ISRAEL21c.

For more information, visit www.oree-inc.com.