In a 1931 essay, Winston Churchill wrote about how he sees the future of food production: “We shall escape the absurdity of growing a whole chicken in order to eat the breast or wing, by growing these parts separately under a suitable medium,” he wrote.

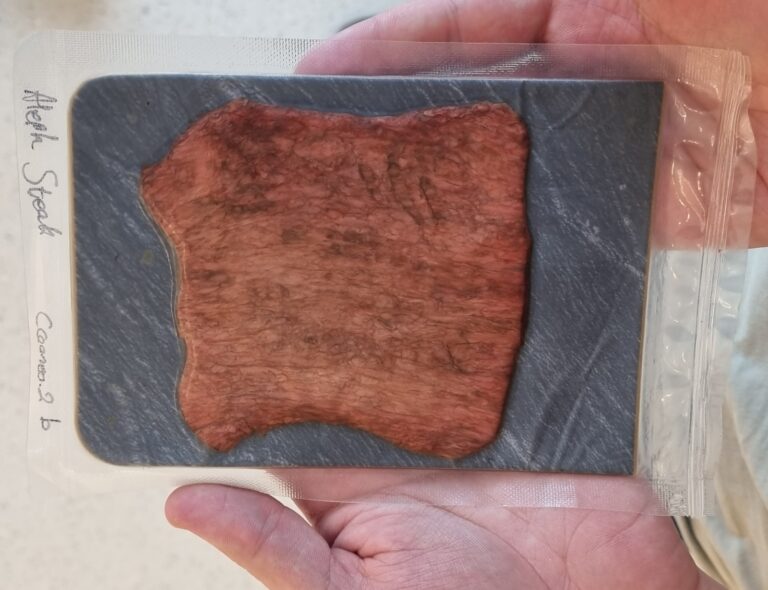

Fast forward some 90 years, and Churchill’s prediction is coming true, thanks in part to Israeli food-tech company Aleph Farms, which has developed a unique method to cultivate steak meat from isolated cow cells.

First to develop cultured steak

“We’re the first company that has managed to develop cultured steak. Not ground beef or nuggets — an actual steak,” says Aleph Farms’ Senior Manager of Marketing Communication Yoav Reisler.

The company’s primary vision is not dissimilar to that of Churchill — to advance food security through the ability to produce meat independent of climate change and dwindling natural resources.

The company grows only the edible parts of cows, using stem cells to generate meat. The focus is solely on beef for now, because of the taxing environmental impact of cattle-raising and because beef is considered the highest quality type of meat.

The Rehovot-based startup, established in 2017, now boasts 150 employees, the majority of whom work in R&D.

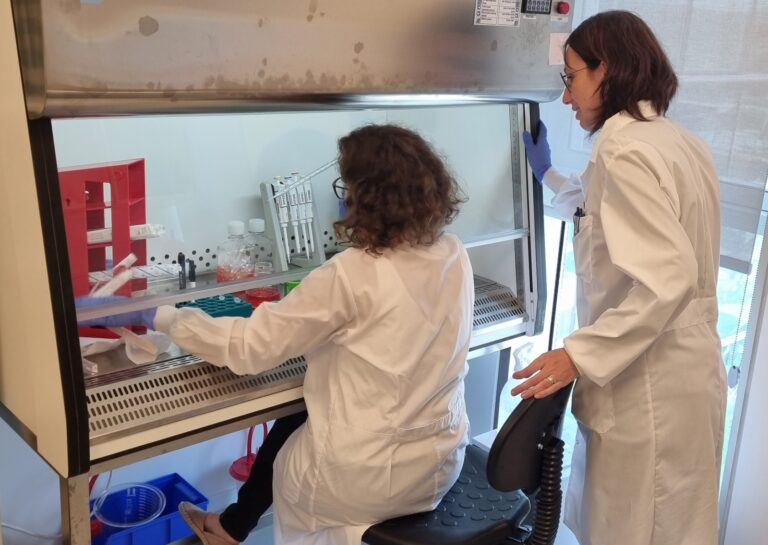

And it shows. In Aleph Farms’ offices, biologists and biochemists pop from room to room in white coats, giving a sense that you are inside one giant medical lab.

“Aleph Farms was established as an initiative of Strauss Group [one of the largest food manufacturers in Israel] and Technion-Israel Institute of Technology, with the cooperation of private investors and the government,” Reisler tells ISRAEL21c.

The initial technology was provided by Prof. Shulamit Levenberg from Technion’s Faculty of Biomedical Engineering, who over the past 30 years has developed a method of growing tissue outside the body.

Levenberg’s vision was to grow human body parts in a lab. While that hasn’t happened yet, her technology proved the perfect launchpad for creating lab-grown meat.

Cultured steaks in supermarkets within 5 years

Aleph Farms has been generating quite a buzz recently. It became the first to cultivate beef in space in 2019, and even boasts Hollywood star and environmental activist Leonardo DiCaprio as one of its investors. In addition, celebrity chef and restaurateur Marcus Samuelsson has recently announced it is joining the company as an investor and advisor.

The company is also part of a social-action campaign that works to integrate Israeli Arabs into the country’s high-tech sector.

The actual product is expected to hit the market by the end of this year, starting with select restaurants once Aleph Farms receives regulatory approvals from Israeli Health Ministry and Singapore’s Food Agency.

Why those two countries?

“Israel and Singapore share a lot of challenges related to food security,” says Reisler.

“They don’t have enough resources to feed the local population, so they’re looking at cultivated meat that could be produced anywhere without taking up land and water needed for cattle.”

In the initial stages, Aleph Farms hopes to produce roughly 10 tons of cultured steak per year, and in the future establish additional production facilities. “The goal is to get to supermarkets in the next five years,” Reisler says.

One of the biggest challenges is to produce at a reasonable cost.

“It requires innovation in production to make the process more efficient. So, in the beginning it is going to be priced similarly to premium beef. But we hope to reduce the cost within a few years from our launch, until we reach price parity with the broader beef market,” says Reisler.

From a fertilized egg to a steak

The first batch of cells the company worked with came from a fertilized egg of a cow named Lucy from California. Lucy apparently was extremely fertile and genetically superior compared to “average” cows.

“Lucy has children all around the world,” Reisler says. He adds that picking a donor is extremely important in order not to end up with “a full tank of problematic cells” from which the meat would be cultivated.

But how does a fertilized egg from a living cow end up as a beefsteak? To answer that question, we turn to Director of Differentiation at Aleph Farms Dr. Natali Molotski.

“To undergo that process, cells need to take on specialized roles, not just multiply. We start working with cells when they are pluripotent,” she says.

Most of us know pluripotent cells by their “mainstream” name — stem cells. Stem cells can become any type of cell, under the right guidance.

“You take an embryonic cell and guide it to be whatever you want — muscle, connective tissue or fat cells. Getting the cells to differentiate in the right way is what my team focuses on,” Molotski tells ISRAEL21c.

“We know how this process happens in the cow’s body, but it takes nine months or so. We need to replicate that process in a few days to reduce production cost. We had to learn to mimic the natural process of cell development, while dealing with regulatory constraints because at the end of the day people are going to eat it. It’s a huge challenge.”

Slaughter-free

The trickiest aspect in the development of cultured meat is recreating the texture, such as tissue and blood vessels. “You need to feed the cells the right food in order for them to have the same taste as animal meat.”

The cells are fed an “animal cell culture media” developed exclusively by Aleph Farms — and it is, well, also cultured.

“The common media consists of serum that is derived from cows. So we developed unique media at this company that is without serum, and later we got rid of all animal components [in cell food],” says Molotski.

“When you work in tissue culture with cells, you don’t even think about it. But when you’re producing it for cultured meat, you can’t feed the cells something that comes — although indirectly — from animal slaughter.”

Even with the most exclusive and expensive food, some cells will not grow up to be steaks.

“We have a machine here that was used for PCR coronavirus tests,” says Molotski. “It helps us understand which cells are more suitable for muscle tissue, for example, and which will not make it to the next round of development.”

Why not simply extract grown cells from a specific body part of an animal and cultivate the meat that way, saving time that it takes to grow a cell from scratch?

“That would be quicker and cheaper,” she concedes. “But, these cells die very quickly. Our cells can be in use forever, so you don’t have to go each time and extract new ones. You also need to take into consideration the issue of genetic stability.”

Although the company now is hyper focused on cultured meat, Aleph Farms’ ultimate vision is lab cultivation of all animal products “from leather to collagen,” adds Reisler.

For more information, click here.