More and more people are making eco-conscious consumer choices, for instance by opting for products that contain natural ingredients.

The problem is that no matter how ecofriendly the contents may be, the packaging itself is often based on plastic, which is detrimental to the environment.

In fact, a recent report shows that the amount of plastics consumed across the G20 nations could surpass 450 million tons per year by 2025 — nearly twice the amount measured in 2019 — unless countries agree to a global ban on unnecessary single-use plastic items.

But replacing plastic in packaging is difficult because most naturally sourced wrapping materials cannot protect the contents inside from light, moisture and oxygen.

This is where Israeli green-tech company Melodea Bio Based Solutions steps in.

“Packaging producers have an urgent need for a sustainable barrier coating that has both water vapor protection and heat sealable properties, and can replace the commonly used plastic PE layer,” says Melodea VP Sales & Marketing Cee Azerraf, a PhD in chemistry.

Filling a gap in the market

The Rehovot-based startup’s pioneering barrier coating made of natural cellulose nanocrystals is resistant to water, oil and aroma. It also has heat-sealing properties.

The cellulose nanocrystals – the building blocks of all plants — are sourced from industrial forests, which Melodea says are the only renewable resource for polymers.

In 2020, Melodea won the Worldstar Packaging Award for developing a sustainable paper-based packaging product. The company also specializes in packaging made of bioplastics and molded pulp.

Its latest innovation, VBseal, can be mass-manufactured on existing production lines, providing environmentally safe packaging for fresh foods, cereals, fast foods, cookies and ice cream as well as detergents and cosmetics. It is fully recyclable and free of paraformaldehyde (PFA) and bisphenol A (BPA).

Commitment to climate action

VBseal is more expensive at the moment than conventional plastic packaging, so it relies on businesses’ commitment to climate action as an incentive to purchase the product.

Many of the world’s largest consumer packaged goods (CPG) companies have made public commitments that 100 percent of their packaging will be recyclable or reusable within the next five to 10 years, and this timeline is being accelerated by public demand, according to Melodea.

Azerraf tells ISRAEL21c that “VBseal can reach the same cost-effectiveness as plastic packaging soon — with the right production process and design.”

Solution to the climate crisis

Melodea invested $500,000 in setting up its first pilot plant and innovation center recently, intended to support companies and packaging producers in their efforts to meet sustainability goals in green packaging.

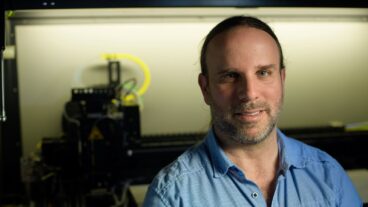

“We offer our clients a location to evaluate their products using our ecofriendly solutions, with full control of the coating process,” says Shaul Lapidot, CEO of Melodea, who has a PhD in biotechnology and biomaterials.

“We can utilize Melodea’s R&D team’s vast knowhow of coatings with optimizing barrier performance, and analyze the results on site, as well as help shorten time-to-market for new products and packages.”

Lapidot says the company, which he cofounded with Hebrew University professor and serial entrepreneur Oded Shoseyov, is excited to work with “producers of food, cosmetics, pharmaceutical and agriculture goods as well as packaging companies at our new plant to help them to reach their goals.”

For more information, click here.