Europe is getting tough on the highly polluting fashion industry, and one major textile machinery brand in Germany is banking on an Israeli technology to green its processes.

Within a few years, every garment imported to Europe will need a digital identity card stating its carbon and water footprints, the presence of dangerous chemicals, and materials used in production.

“This will introduce transparency and revolutionize the textile industry,” said Axel Pieper, owner of Brückner Textile Technologies, which supplies a quarter (5,000) of the world’s fabric finishing machines.

Fabric finishing, the last stage in textile production, is where the fabric is dyed and/or coated with antibacterial, odor-repellent, water-repellent, UV-blocking or other substances. According to Pieper, this is the most polluting step in textile production.

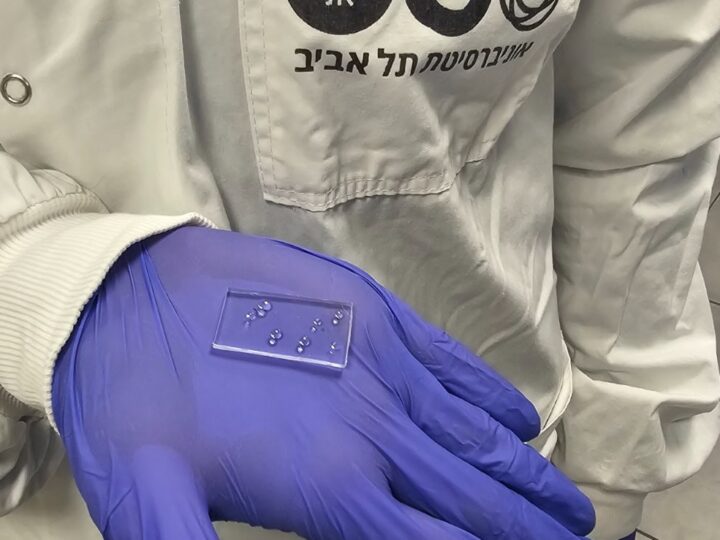

Brückner therefore partnered with Israeli technology company Sonovia to develop a textile finishing machine that uses soundwaves to infuse desired properties into fabrics without polluting materials and adhesives.

This technology uses much less water and energy than traditional processes, significantly reducing polluting emissions.

The Sonovia-treated fabric is more sustainable because it holds up better after repeated washings, further reducing pollution caused by discarded textiles.

The first jointly developed SONOfix machine was recently installed at Delta Galil Industries in the Galilee to produce underwear and sports clothing for brands such as Tommy Hilfiger, Calvin Klein and Adidas.

Sonovia is planning to deliver additional machines to textile plants in Taiwan and Central America that manufacture clothing for brands such ase Adidas, Nike, The North Face, Decathlon and Lululemon.

Pieper expects the coming regulation will convince many textile manufacturers to follow suit; revenue in the first phase is expected to reach tens of millions of dollars.

“I am convinced that Sonovia’s technology is the best way to reduce the carbon and water footprint not only in the production of textiles but also in the use of textiles,” said Pieper.

Earlier this year, Sonovia partnered with Italian denim manufacturer PureDenim to transform indigo dyeing by reducing the intensive use of water and energy and improving dye durability.

Igal Zeitun, CEO of Sonovia, said the textile industry is “desperately looking for technological solutions that will allow even partial reduction of pollution while maintaining the same product quality. Sonovia’s technology allows them to achieve the same quality and even better with a dramatic reduction in pollution.”