Fashion is one of the least sustainable and most polluting industries.

Apparel manufacturing consumes vast amounts of water and causes up to 10 percent of global carbon emissions due to energy-intensive production and shipping.

And every year, about 13 million tons of unsold apparel are landfilled or incinerated.cao

As individuals, there are fashion choices we can make to leave a lighter footprint on the planet.

But making the industry more sustainable and less polluting is a big challenge. New technologies, some of them invented in Israel, are forging a greener path forward for fashion designers, manufacturers, retailers and consumers. Here are some of the most promising ones below.

Sustainable silk

The traditional production of silk is inefficient, land-intensive and polluting. In addition, the industry involves slave labor and animal cruelty as the silkworms are steamed or boiled alive.

Using biomimicry, Jerusalem-based Seevix Material Sciences has created “a state-of-the-art animal-free biopolymer material, inspired by spider silk, through a unique process akin to nature,” says cofounder and CEO Shlomzion Shen.

That process, a patented recombinant DNA technology within a controlled micro-environment, induces spider silk proteins to self-assemble spontaneously into silk nanofibers.

The resulting biopolymer material, SVX, is exceptionally strong, antimicrobial, odor-resistant, recyclable, flexible, and resistant to wear and tear.

SVX has many potential uses — from condoms to cosmetics, from medical devices to scaffolds for cultivated meat. Textiles are also a planned core application with significant environmental benefits, says Shen.

“ASICS is collaborating with Seevix to develop next-generation, high-performance and sustainable sportswear and sports shoes,” she says.

Seevix is recognized as a “disruptive tech innovator of next-gen materials” by the Material Innovation Initiative, a US nonprofit think tank that accelerates the development of high-performance, animal-free, environmentally friendly materials to replace silk, wool, down, fur, leather and their synthetic alternatives.

Printing on fish skin

Israel-based multinational company Kornit Digital is a global leader in sustainable, on-demand, digital fashion and textile production technologies.

In 2022, its 20th year, Kornit estimated that its portfolio of technologies helped producers in more than 100 countries save 1.5 billion kilograms of greenhouse gas emissions, 252 million kilowatts of energy and 320 billion liters of water.

Kornit also dabbles in experimental projects like FISHSkin – a joint endeavor with leather designer Ori Topaz, who teaches bio-design at Shenkar College of Engineering, Design and Art.

Funded by the European Union’s Horizon 2020 RISE program, FISHSkin involved a research consortium of organizations from six countries. With unique Kornit hardware, Topaz made a collection of leather handbags demonstrating the feasibility of digital printing on discarded salmon skin.

“The project expresses an ecological and innovative use of a raw material that is waste in the fish industry and one of the polluting factors of the environment,” said Ira Farber, Kornit Digital’s Chemistry Group Manager.

“The final product of the project incorporates both a design aspect and a technological aspect, for example the unique printing process that includes matching of the chemistry of the ink to the new substrate and the drying processes.”

Topaz called the project a breakthrough for the textile and accessories industry.

“The work with fish skin serves as a proof of concept for combining leftovers in an applicable, sustainable and aesthetic way, with the aim of stimulating change in the world of design and opening up new possibilities for designers.”

Revolutionary denim dyeing

The indigo dye market for the jeans industry is estimated at $1.5 billion a year.

However, traditional indigo yarn dyeing processes require an average 60,000 liters of water per process and use polluting chemicals such as hydrosulfite.

D(y)ENIM, a chemical-free, ultrasonic indigo dyeing technology from Israeli green-tech company Sonovia, drastically reduces water usage, chemical waste and energy expenditure in the dyeing process.

France’s Kering (the global luxury conglomerate behind iconic brands such as Gucci, Balenciaga and Saint Laurent) and Italy’s PureDenim recently integrated D(y)ENIM into their production lines.

Fellow Israeli company Avco will promote and sell the ecofriendly indigo dye and technology to global textile and fashion companies.

Sonovia, a graduate of the Fashion for Good accelerator, anticipates additional partnerships with leading manufacturers with a focus on reducing environmental impact, said Sonovia cofounder Shay Herchcovich.

Digitizing uniform production

Optitex, a multinational Electronics For Imaging company headquartered in Rosh Ha’ayin, is known for its digital patternmaking and 3D design software solutions for the uniform and workwear industry.

Digitalizing uniform production for sustainability enhances speed, efficiency and fit, while reducing waste and costs.

Optitex won an award at the Professional Clothing Industry Association Worldwide 2023 Awards for innovation in personal protective equipment (PPE) clothing.

“Optitex’s end-to-end software enables protective clothing makers to digitally design, virtually test fits, and optimize manufacturing. Their tools have developed high-performing, comfortable gear for military, law enforcement and hazard protection. With unmatched digital patternmaking and lifelike garment simulation, Optitex provides an integrated solution for protective clothing design to production, making them an innovation leader,” the PCIAW judges said.

Amir Lehr, Optitex CEO, said: “This accolade is a testament of our commitment to the PPE industry, and our keen understanding of professional uniforms, which beyond a fashion statement, demand functionality and precise fit.”

Optitex recently released its newest digital collection of YKK zippers, buckles and cord stoppers for designers to use in virtual samples of apparel, tactical wear, tech textiles and backpacks. The actual fasteners, which are difficult to recycle or upcycle, are used only in final products.

Sketch to store

Browzwear software helps more than 1,000 global apparel brands build efficient and collaborative “sketch to store” workflows.

The company’s products enable brands to create and share digital prototypes of infinite variations; validate fit and style via a digital twin of the physical garment; obtain customer feedback prior to production; present collections through 3D catalogs and virtual showrooms; and generate a production-ready “tech pack” for manufacturing.

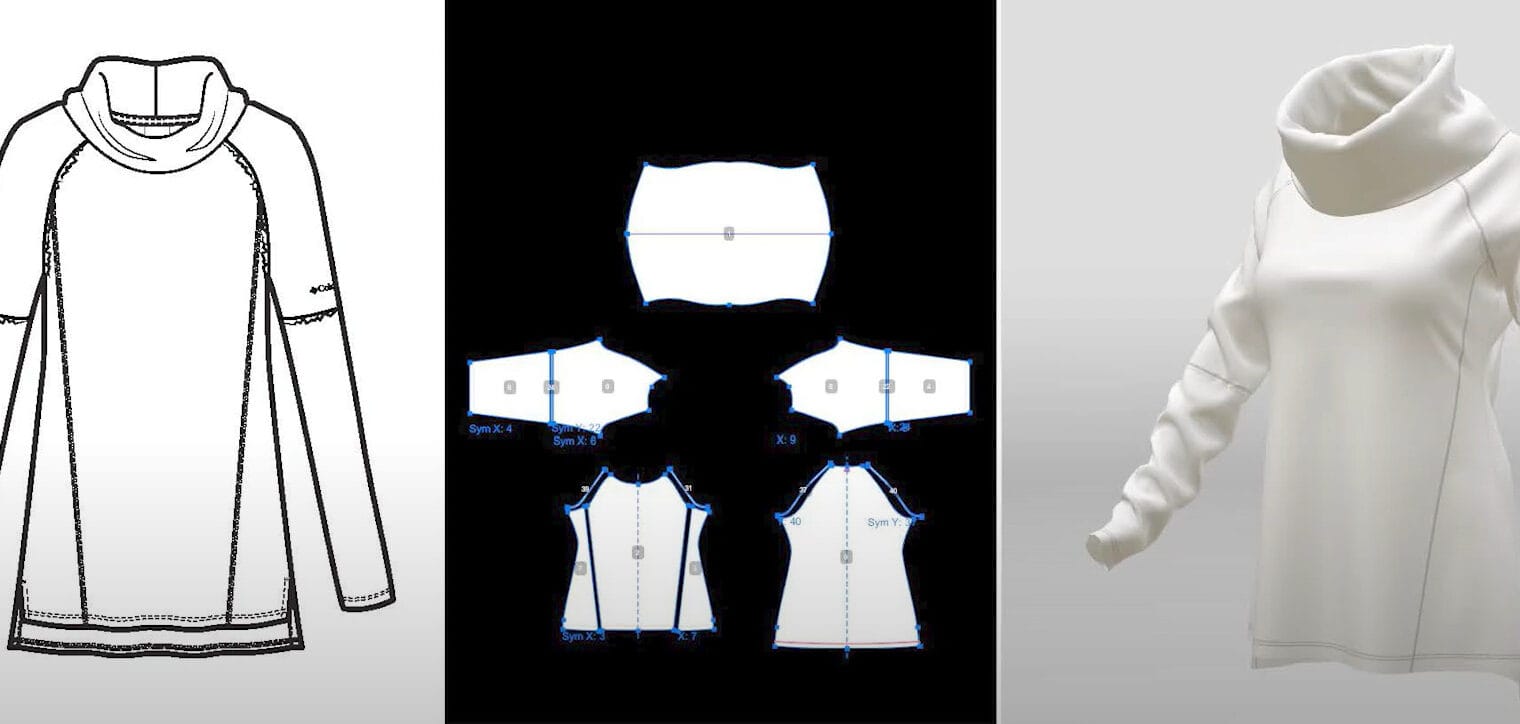

One recent example: Browzwear 3D fashion design software helped Columbia Sportswear streamline internal processes around pattern changes, grading and sizing — a typically lengthy and tedious process.

“3D changed communication and collaboration a lot,” said Johanna Lindstrom, a fit engineer at Columbia. “I can communicate what kind of pattern changes I want to make to a prototype that I receive now that we have much better tools to communicate these changes, not just verbally, but in the program.”

Once the design teams learned how to use and trust the accuracy of the Browzwear software, Columbia successfully eliminated multiple rounds of physical prototyping, making informed decisions over digital twins before producing a physical prototype.

Click here to read how Browzwear handled the upskilling of garment workers in China and Bangladesh as technology makes mass fashion more efficient and environmentally friendly.

Click here to read how Browzwear helped Delaware-based Lycra Company create a more sustainable development space, saving time and reducing waste.

Reduced returns

Consumers return up to 40% of apparel and shoes purchased online. In 70% to 80% of cases, customers say the item fit poorly or didn’t look good on them.

Much of that returned merchandise, which takes lots of energy to ship back and forth, ends up in landfills. Israeli virtual fitting technologies are tackling this problem.

Zeekit developed the first dynamic virtual fitting room, using augmented reality to allow customers to see an avatar of themselves – or models of different body types — in any item of clothing on an ecommerce website. Acquired by Walmart in 2021, Zeekit has helped companies such as ASOS, Tommy Hilfiger and Macy’s improve conversion rates and reduce return rates.

Nettelo offers a suite of SaaS (software as a service) and mobile applications for remote body measurement and fitting. Its patented 3D body-scan technology is used by businesses and consumers to determine size and fit before buying clothes in order to decrease returns and improve conversion rates and shopping experience.

MySize pioneered the AI-driven FirstLook Smart Mirror that tells shoppers what size they’d take in various clothing brands. Using sensors in their own phone, customers map their body and receive a private “MySizeID” enabling them to buy correctly fitting clothes online from manufacturers such as Levi’s, Lacoste, Nautica and Gant, or in one of more than 1,000 retail stores with a FirstLook Smart Mirror. MySizeID can be updated as kids grow or body contours change.

Sizer has won several retail-tech awards for its virtual sizing products including a consumer mobile app, embedded web app and standalone sizing kiosks for on-location scanning of multiple users. In 2021, Sizer partnered with North American intimate apparel brand Wacoal to launch an industry-first solution, the mybraFit app.