From the moment a tree is chopped down, wood waste starts to accumulate. Splinters of bark and wood on the forest floor. Mountains of shavings in sawmills, lumbermills and papermills.

Some of this waste is turned into commercial products such as mulch, animal bedding and biofuel. The majority goes to landfills or gets incinerated, contributing to greenhouse gas emissions by releasing the carbon dioxide the trees absorbed from the air.

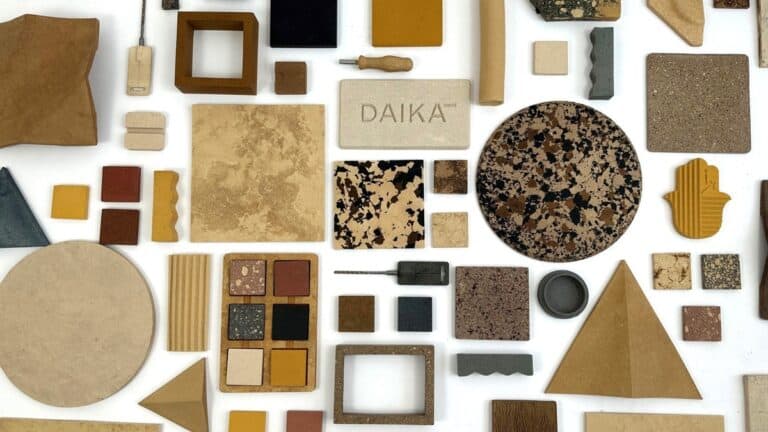

Israeli scientist Michael Layani found a better option: Turning wood waste into Daikawood, a new natural material to replace petroleum-based and hazardous wood-like materials for many applications.

Layani earned his PhD in materials science at the Hebrew University of Jerusalem and planned a career in academia. He’d published papers and advised several startups.

And then, while managing the 3D & Functional Printing Center of nanomaterials expert Prof. Shlomo Magdassi in 2018, he initiated a project with PhD student Doron Kam to create 3D printer “ink” from organic wood derivatives.

“When I held the samples in my hand, I kept caressing them and I felt there was something here far beyond another academic paper,” Layani tells ISRAEL21c. “It was something I was really in love with.”

Star power

This project uniquely combines the expertise of two renowned Hebrew University serial inventor-entrepreneurs: Magdassi in materials science and 3D printing, and Faculty of Agriculture Prof. Oded Shoseyov, who has found multiple uses for cellulose, an abundant, sustainable substance found in every plant and tree.

“We wanted to open a new door in the field of 3D printing,” Magdassi tells ISRAEL21c.

“I believe in collaboration with researchers from different disciplines, and this is a collaboration with a very good synergy and outcome. It all came together beautifully.”

After licensing the IP from the university’s Yissum tech-transfer company, Layani and the two professors launched Daika in 2020.

Daika, Layani explains, has a double meaning. It’s a Japanese style of carpentry that doesn’t use glues or screws; and in the ancient semitic language Aramaic, daika means “learn from it.”

“We see ourselves as a company that can upcycle wood waste from many sources, even textile waste, without creating new waste streams of our own. Our vision is that in 10 years everyone will know there is a circular, sustainable way to do it.”

Completely circular

Daikawood is made by grinding wood waste and mixing in water and organic ingredients, including cellulose and food industry byproducts, to mimic the chemistry of wood.

“At first, this raw material is like dough and can be further processed with molding, pressing, extrusion or layered manufacturing to form a product. Because we control the production process from first stage to final product, we can dye it and create patterns in it,” Daika CEO Shlomo Amir tells ISRAEL21c.

After curing in a temperature-controlled room for a few hours to a few days, Daikawood hardens into a raw material that is, Amir says, “better than natural wood. It’s at least as strong, if not stronger, and has the highest possible fire retardancy for wood.”

Daika’s novel molding and printing process cuts down on manufacturing waste and excess.

“You can polish and mill Daikawood. The waste from these processes is then reused, so our cleantech mass manufacturing process is completely circular.”

Based in Rosh HaAyin, Daika was supported initially by Terra Venture Partners and the Israel Innovation Authority. Albert Douer, chairman and co-CEO of UBQ Materials (which makes a plastic alternative from household trash) later joined as a strategic investor and adviser.

Pilot stage

Daika is now in the pilot stage, says Amir. In this first phase, Daika sources all its wood waste from Israeli sawmills.

The company will soon raise seed funding to build a small plant in Israel that could deliver commercial products by mid-2024. Larger plants are planned with strategic partners in the US and Europe, with initial delivery of Daikawood estimated for the first quarter of 2025.

“Next to our office we produce samples for potential customers and partners. We ran a few POCs [proofs of concept] for companies such as office furniture manufacturer Steelcase,” he tells ISRAEL21c.

Daikawood starred in an award-winning project of the D.Dlab (Disrupt.Design) computational design and advanced manufacturing solutions lab at Israel’s Technion-Israel Institute of Technology, under the direction of Assistant Prof. Shany Barath.

The lab’s WoodenWood project developed robotic tools to 3D print Daikawood into woven textile surfaces resembling rattan for sustainable seating products, demonstrating the potential for enhanced wood performance using zero-waste design principles.

The WoodenWood project received the international Design Educate Awards 2023 Gold Prize for the best ideas and implementations of architecture and design. Additionally, the project was on view during Milan Design Week 2023 and selected by Fuorisalone.it as one of the top 12 projects related to sustainability.

Patented recipe

Daika isn’t the only company making processed wood from wood waste, but it’s the only one using natural substances as a binder instead of epoxies and other petroleum-based materials, Amir says.

Daikawood is made from a precise recipe protected by one approved patent and more to come. The exact ratio of materials is the secret sauce, says Amir.

“There is real innovation and a lot of knowhow behind our company, gathered first in Hebrew University labs and then in our company. We can supply a 100 percent natural material with no thermoplastics, providing designers with new possibilities and bringing competitive costs to current plastic and wood industry standards.”

The technology can handle wood byproducts from any waste stream, including industrial carpentries and municipal landscaping.

“We have the ability to reduce billions of tons of waste wood that are not currently used in a real circular economy, reducing time and cost in construction and consumer products,” says Amir.

For more information, click here.