Everyone knows that weed isn’t just for recreational smoking. Cannabis has amazing medicinal properties that Israelis have led the world in discovering and commercializing.

And now Israel has its first house made out of hemp, the fibrous part of the cannabis plant.

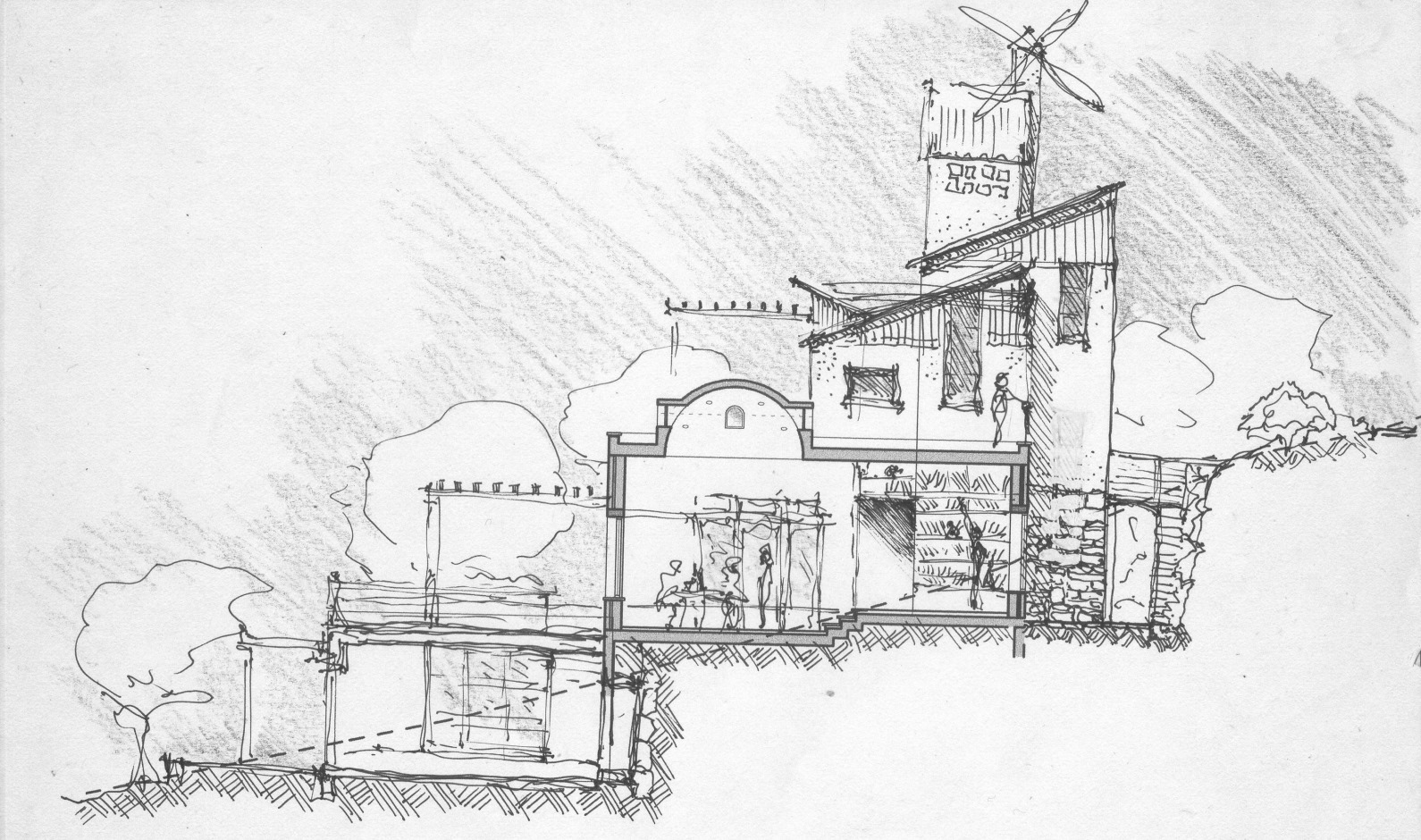

The innovative private home sits on the southern slope of the Israeli artists’ village of Ein Hod, facing the Mediterranean Sea.

The property’s owners desired a home that would be an archetype of sustainable building, blend with the beauty of its natural surroundings, and include spaces for workshops and guests.

Historically, this Mount Carmel hillside was a quarry providing the building stone for the village houses. Tav Group of Haifa, pioneers of eco-architecture and design in Israel, constructed the 55-centimeter-thick walls of the hemp house’s lower ground-floor studio from stone carved out on site to make room for the foundation. The same stone was also used for paving throughout the house.

The walls of the main floor are built of hemp hurd — the soft inner core of the hemp plant stem, known to be highly absorbent, rich in cellulose and possessing great thermal and acoustic properties.

The hurds are bound with hydraulic lime and cast in a timber frame, a unique ecological construction method providing superior thermal insulation. Interior partitions, made of rammed earth cast on wooden frames, also contribute to the high thermal mass of the house.

The exterior is coated with lime-based natural plaster and the interior surfaces are treated with a thick layer of earth-based plaster, to further increase climate moderation.

“The owner of the house is very dedicated to environmental issues, so he went and learned about this method in France and imported the whole idea to Israel,” Tav Group founding partner Maoz Alon tells ISRAEL21c.

“Centuries ago and up to the beginning of the 20th century, one could find straw and mud houses in rural areas here. But mud is susceptible to rainfall erosion versus lime, which eventually becomes limestone, and cannabis hurds, which are much stronger and more durable than straw.”

He says that the innovation of Israel’s first hemp house “is in the fusion of novel technology with traditional, local proven architectural patterns with natural materials” sourced from Israel and abroad.

The hemp, grown specifically for construction purposes, was ordered from France as was specially aged lime to augment the Israeli lime. The wood for the timber frame was grown in a Canadian sustainable forest.

“These natural materials “smell and feel so good throughout the building process,” Alon says.

The house’s unusually small ecological footprint was enhanced by several elements.

A south-facing courtyard opposite the entrance hall catches the sea breeze. Towards the north, a service court acts as a wind chimney. Water conservation aspects include a graywater system, a rooftop rainwater gathering system and compost toilets. Rooftop solar panels and passive air conditioning provide natural heat and cooling.

The 250-square-meter abode was ready for the family to move in last winter. Though construction by a team from the Bottz Group (botz means “mud” in Hebrew) took less than a year, the planning and design of the project began back in 2009, says Alon.

The cost was approximately 150 percent higher than a conventional home of a similar size, but both Bottz and Tav hope to bring down the price (and the planning time frame) substantially for future customers now that they’ve perfected the process.

“Architecture goes far beyond the material,” says Alon. “It is about the creation of spaces to dwell in that are physically supporting and spiritually lifting. This quality can hardly be caught in a photograph or be conveyed in words. I hope the Ein Hod house will be judged favorably in this broader context.”

For more information, click here.