Elad Mor, an Israeli mechanical engineer specializing in structural optic coatings, took a refreshment break while experimenting with transferring light onto surfaces without using pigments or dyes.

When he raised the chilled drink to his lips, he had a eureka moment.

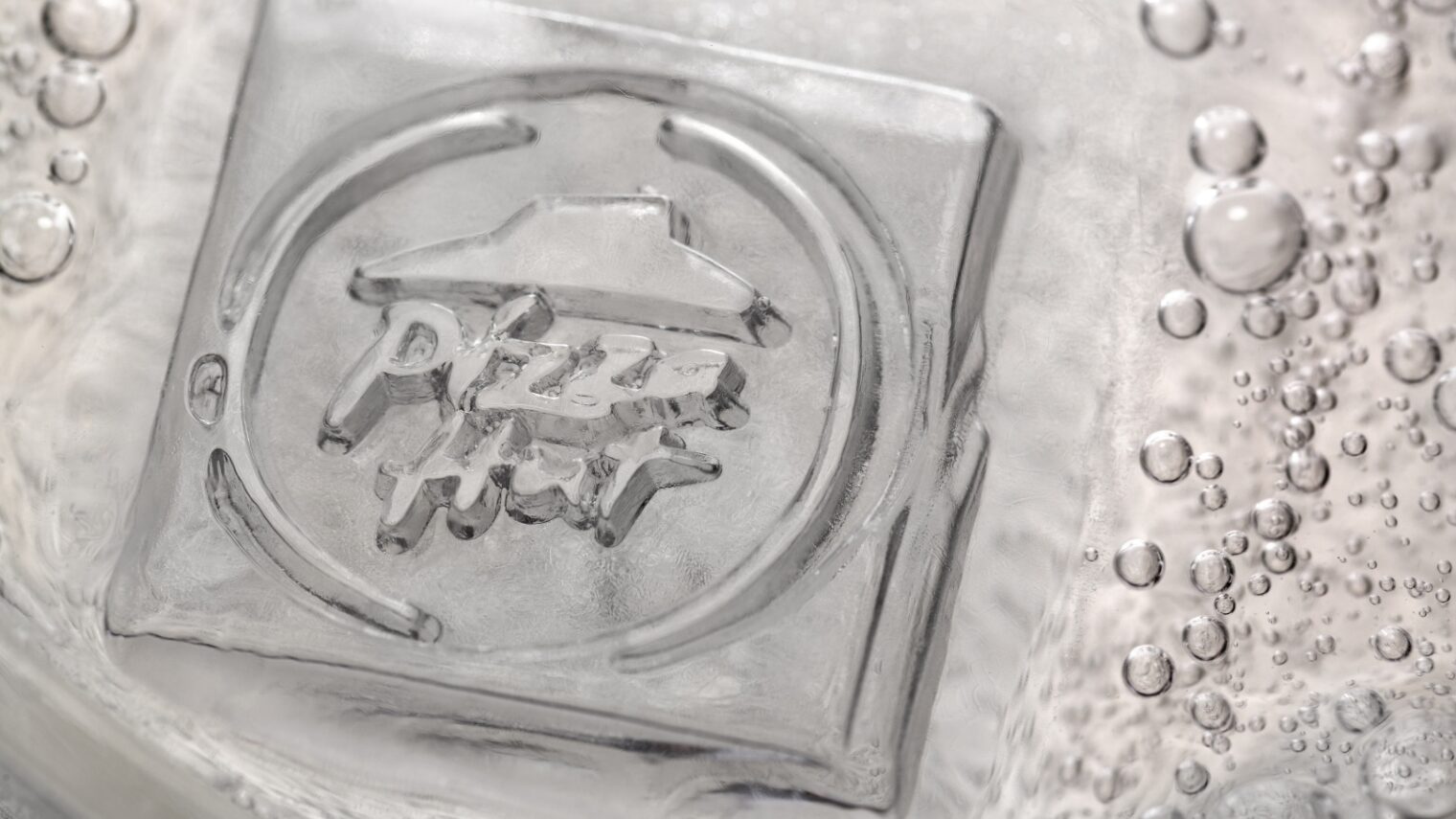

Ice cubes come very close to the eyes of the drinker – a perfect promotional medium if one could embed a logo or image in the cubes without any dye that would spoil the drink.

“We would have to do it with 100 percent water. And that’s exactly what we are doing today: putting high-resolution images in the center of the ice cube without any additives at all,” Mor tells ISRAEL21c. “It’s like we discovered a whole new island.”

That is the basis of Icebow, a two-year-old startup in Jerusalem. VLX Ventures and Cresson Management poured $650,000 into the cool venture.

“Ice, a surface no one has ever touched, can finally be altered,” says Sagi Katz, the head of business for Icebow. “It was a big challenge, and engineers love a good challenge.”

You won’t see Coca-Cola logo ice cubes in your cup of Coke so soon, however. Producing the cubes requires the combination of two entirely new technologies to be integrated with commercial ice-making machines: a “dry harvesting” technology and an imprinting technology.

Mor has invented both.

Ice-makers adopting both technologies will be able to offer customers a win-win: the ability to print images in the center of the ice cubes, while using dramatically less energy and enhanced productivity compared to current “wet harvesting” techniques.

“So, the mission is to turn standard drinks into premium ones, all while helping save the planet,” Katz tells ISRAEL21c. “In the US alone, energy costs for commercial ice machines add up to $1.62 billion per year.”

Icebow is in advanced discussions with three of the world’s largest ice equipment manufacturers on integrating and commercializing Mor’s patent-pending dry-harvesting technology as a first step toward putting branded photonic ice cubes in your drink.

“Today, ice cubes are produced in batches on evaporators made of hard metal. To detach the ice at the end of the freezing process, heat is applied to melt the surfaces that touch the ice,” explains Mor.

Wet harvesting translates to a lot of wasted energy, plus wear and tear on the machine as it transitions from freezing to heating. And Mor’s photonic ice cubes can’t be made this way because the embossed images would melt off.

Tests show that Mor’s dry method accelerates ice-cube harvesting and increases energy efficiency and productivity by up to 30 percent over wet harvesting. And without having to generate radical changes in temperature, the machines probably would be more reliable and long-lasting.

“Together with ice-makers, we’re looking to make a big dent in the market,” says Katz.

Big brands, restaurant and hotel chains are getting excited about the embossed ice, says Katz. “We are looking for their influence to encourage the makers of their ice-cube machines to adopt Icebow’s branded photonic ice cube technology.”

Between 600,000 and 700,000 ice-cube machines are sold every year worldwide, with the US market accounting for about 40% of that number.

“Turning cold drinks into a premium experience, while saving the environment, requires the disruption of a multi-billion dollar industry, which is what excites us and our investors,” says Katz.

“We believe this is a cool new way for brands to engage with customers, offering new levels of intimacy and brand affinity.”