Collagen is harvested from the leaves of CollPlant’s genetically engineered tobacco plants.The plants growing at CollPlant’s greenhouse in the north of Israel look much like any other tobacco plants. Appearances, however, are deceptive. These plants, worth millions of dollars when they are harvested, are packed full of recombinant human collagen for use in aesthetic and reconstructive surgery.

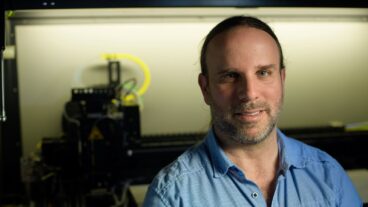

It sounds more like science fiction than real life, and even Prof. Oded Shoseyov, who helped create the genetically engineered plants, acknowledges that it is unique. While other researchers have managed to insert human genes into plants, they have only managed to introduce one gene. Shoseyov is the first in the world to introduce five different human genes into a single plant cell to create a superior fully functional human collagen product.

Collagen is one of the most important proteins in the human body. Twenty-five percent of all dry material in the body is made of collagen. Tendons are almost 100% collagen, skin 70%, and bone 50%. “It’s the scaffold of the human body,” Shoseyov, CollPlant’s chief scientist, tells ISRAEL21c.

As a result collagen today is in great demand for anything from aesthetic facial procedures – such as lip augmentation, or wrinkle treatment, to plastic surgery, tissue regeneration, wound and burn healing, and orthopedics. The facial aesthetic industry alone is expected to be worth $1 billion by the year 2010, while sales of collagen-based products are estimated to be now worth more than $10 billion worldwide.

Until recently the majority of collagen used in the market came from cows or pigs. The problem with this, however, is the growing concern over infectious diseases passed on from animals to humans, in particular Mad Cow Disease. In certain countries like Japan it is now illegal to use collagen from animals, while in January last year, the FDA suggested that it may limit the use of bovine derived collagen in medical devices.

Another source of collagen is from cadavers – again problematic. “We know the person died, but we don’t know from what,” says Shoseyov. Cadavers also provide only a very limited source of collagen.

The research behind CollPlant was developed in the Rehovot lab of Shoseyov, a professor at the Faculty of Agriculture at the Hebrew University of Jerusalem. Initially he had no plans to get involved in this field, but a few years ago was approached by an Israeli company looking to create a new source of human collagen. “They had identified a huge need for such a product in the market,” says Shoseyov.

The project never took off, the company moved into a different area and Shoseyov, who is renowned for his innovations in the fields of plant transformation systems and protein engineering, forgot about the idea. Then four years ago he was approached by the management of the Meytav Technological Enterprises Innovation Center, a technology incubator in Kiryat Shmona. The incubator was looking for projects to turn into viable companies and Shoseyov remembered the earlier idea.

The incubator liked the proposal and gave Shoseyov seed funding to start a new company, CollPlant. “One year later we had collagen in plants,” says Shoseyov. “It was a very concerted effort.”

CollPlant spent three years at the Meytav incubator during which time it also received angel investment of just under $1 million. In 2006, CollPlant received another $4.5 million in funding from Docor International Management, Pontifax Fund – founded by Eli Horovitz, and investor Moshe Arkin. Today the company is in the process of raising $10 million from new and original Israeli and US investors.

The headquarters of CollPlant, which employs 35 people, is now based at the Weizmann Science Park in Rehovot, while the greenhouses of 1,000 square meters remain in the north. The company can produce tens of thousands of transgenic plants per year. The collagen is extracted from the leaves of the tobacco plants, which are harvested every five to six weeks.

There are many benefits to CollPlant’s plant-derived collagen according to Shoseyov, including the fact that it is free of any potential viral hazards. “It’s safer, more cost-effective, and much more homogenous than used material extracted from tissue,” he claims. “It’s like building a wall from bricks. You can take apart an old wall and use the bricks from it to make a new wall, but if you manufacture new bricks and use these to make a wall it will be much nicer, stronger and more homogenous.”

In addition, while most people tolerate collagen from animals, some have an allergic reaction. That’s a problem because it means that everyone must do a pretest to see how their immune system reacts. This normally takes a month. “With facial aesthetics the client wants it now. They don’t want to wait. For burns patients it’s ever worse. They could die if they have to wait a month,” says Shoseyov.

CollPlant expects to begin selling its collagen by the end of this year. Clinical trials are not necessary, to get FDA and CE approval, the company needs only to carry out trials in toxicology and safety, which have already been successfully carried out according to Shoseyov. Testing of CollPlant’s collagen has shown that it is similar to type 1 collagen naturally present in human tissues. “Our data shows it’s very safe and should be no problem to use as a replacement of today’s collagen,” says Shoseyov.

The company is now negotiating joint venture co-development agreements with strategic partners. By the end of this year, Shoseyov believes the company will have signed technology transfer agreements with two companies, one large US company, and a smaller Israeli one.

“We have already given samples and received positive reactions,” says Shoseyov. “We are confident we will sign agreements this year.”

First applications are likely to be in facial aesthetics, specifically wrinkles and lip augmentation, followed by scaffolding for bone repair.

In the future, the company also intends to start developing its own unique products in the field of wound healing and orthopedics.

“This isn’t just a commercial achievement, it’s also a scientific one,” says Shoseyov. “This will have a big impact on the market. We are getting so many calls and approaches from companies all over the world who are interested in using our collagen. The industry is looking for an alternative and we are providing it.”![]()

Slashdot It!![]()