The genetically produced fibers in insect cells are shown against a backdrop of a spider and its web.A remarkable Israeli achievement may have far-reaching implications in future development of products ranging from micro-conductors and optical fibers to fishing rods, surgical thread and even clothing.

For the first time anywhere, scientists from the Hebrew University of Jerusalem and from Germany, have succeeded in producing self-assembled spider web fibers under laboratory conditions, outside of the bodies of spiders. This fiber is significantly stronger than the silk fiber made by silkworms.

The achievement by the research team, described in an article in the current issue of Current Biology, opens the way to commercial development of this spider fiber for numerous industrial applications.

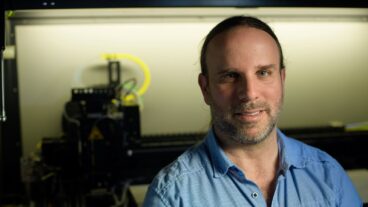

“Only the imagination can limit what can be done with this. It’s really remarkable – it’s elastic and strong at the same time,” Hebrew University developmental biologist Dr. Uri Gat told ISRAEL21c.

Gat, along with doctoral student Shmulik Ittah and research assistant Shulamit Cohen of the Department of Cell and Animal Biology in the Silberman Institute of Life Sciences at the Hebrew University, joined Dr. Thomas Scheibel and doctoral student Daniel Huemmerich, biophysicists at the Technical University of Munich, and Fritz Vollrath of Oxford University to conduct the two-year research.

“From a practical viewpoint, mass production of fibers whose diameter is one-thousandth of a millimeter is likely to be useful in the future for the manufacture of bulletproof vests, surgical thread, micro-conductors, optical fibers and fishing rods,” said Gat.

Natural webs contain silks from certain proteins and in order to duplicate such properties the scientists used genes from the garden spider which contain a protein known as dragline silk.

Characterized by its strength and elasticity, dragline silk is six times stronger than nylon and steel fiber of the same diameter

Silk has been in use by mankind for thousands of years. However, unlike silkworms, spiders are territorial in nature and thus not subject to domestication and commercial growth in quantities.

Scientists have attempted to create spider’s webs independently of the spider itself through genetic engineering by manufacturing the proteins, which constitute the silk fibers of the webs, through the use of bacteria, yeast, plants and mammalian cells in tissue culture. But these efforts were unsuccessful in producing fibers with properties similar to the natural ones.

Gat explained that he began working on the project with Scheibel, while both were studying in the U.S.

“We’ve been working on the project for about two years, while were both doing our post doctoral work at neighboring labs at the University of Chicago. We were both researching different types of protein fibers, and he mentioned the spider silk web – the strongest silk web in existence. I suggested we try to express the genes, the coding of the spiders using a systematic approach based on the Baculovirus expression system,” said Gat.

After two years, the Israeli-German scientific team has succeeded, through techniques of genetic engineering, in creating spontaneous production of spider web fiber in insect cell cultures. These fibers are equal in their chemical resistance characteristics to those produced by the spider.

Mass production of such fiber in the future can be used industrially in various areas which require fine applications.

“We’ve already begun steps to commercialization of the researchthrough Yissum – the Research Development Company of the Hebrew University in collaborative efforts with the German team. We’ve done the science – the basic product. Now, we have to take the step to establish means to produce the fibers on a large scale – there are other scientific hurdles we have to pass as well,” Gat said.

Spider webs consist of fibers (spider silks) produced by specific proteins. In order to artificially synthesize these proteins, the researchers utilized sections of the genes of the garden spider (Araneus diadematus), which are involved in the manufacture of these proteins.

The spider spins its web from various types of fibers, including the fiber known as dragline silk, which is characterized by great strength and elasticity. It is six times stronger than nylon and steel fiber of equal diameter and serves the spider as a “lifeline” in case of falling. This fiber is made up primarily of two proteins, ADF-3 and ADF-4, which are genetically similar and are produced in a gland in the abdomen of the spider. The process by which these proteins pass from the moment of their production until their excretion as fiber was not understood until now.

In their laboratory experiments, the researchers introduced the genes, which encode the two dragline silk proteins, into an insect-infecting virus, known as baculovirus. These genetically engineered viruses were then grown in cultures of cells derived from a type of caterpillar called the fall armyworm.

“Since spiders and insects are both arthropods and since their genomes are more closely related to each other than to those creatures with which prior experiments were conducted, we felt that we would be able to produce spider fibers using these insects,” said Gat. “For this purpose, we developed a methodology for producing great quantities of the appropriate proteins, which is based on infecting the insect cells with the genetically engineered virus, in order to produce the fiber.”

After the engineered viruses infected the insect cells, the cells began producing the proteins, and subsequently ‘spider’ fibers spontaneously formed in them. However, – unlike in spiders – these laboratory-produced fibers were made up only of the ADF-4 protein, while the ADF-3 protein remained dissolved. Nevertheless, these fibers were identical in their diameter to that of real spider fiber and were found to be equal to – and in certain aspects even exceed – the chemical resistance quality of the spider-created fiber.

The researchers are now hoping to be able to create conditions, which will make it possible to produce the spider fibers in quantity without the limitations of having to do this within insect cells.

“The research enabled us to determine the close connection that exists between the sequence, structure and functions of the proteins,” said Gat.

So Spiderman, take that. The next generation of web spinning will be taking place in Jerusalem.