OrganiTech is developing a series of growing machines for different kinds of produce.Lots of people are eating lettuce these days. In fact, the leafy stuff is a $20 billion business in the U.S. and an $18 billion business in Europe.

The problem, however, is growing lettuce that can remain fresh without traces of chemicals, soil or bugs, and then keeping the supply fresh during shipping. One Israeli company has figured out a way, growing lettuce hydroponically – that is – cultivating produce without soil.

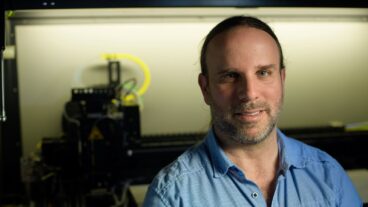

“Lettuce has become like bread,” says Lior Hessel, CEO and a co-founder of OrganiTech, which is based in the northern town of Yokneam. “It has to be on the supermarket shelves 12 months a year.”

According to figures gathered by OrganiTech, the rise in demand for lettuce – particularly the popular pre-washed and packaged bags of greens – has become difficult to meet. Lettuce can be grown only in sunny regions where the temperature doesn’t fall below zero. For the U.S., those conditions are limited to California’s Salinas Valley and Mexico, while sunny Spain has become the main supplier for Europe.

But because of their relatively short shelf life, heads of lettuce have to be shipped quickly so that they remain crisp and fresh. Given the distances between the West and East coasts in the U.S., or between northern and central Europe, fresh lettuce is generally transported in refrigerated trucks, an expensive proposition that hikes up prices on the already pricey item.

“Lettuce in Boston that comes from Salinas rises by at least 30 cents,” Hessel told ISRAEL21c. “It’s the same in Europe. Lettuce is a lot more expensive in Finland when it’s coming all the way from Spain.”

A robotics engineer by trade, Hessel and his brother, Ohad, began thinking about solutions for lettuce cultivation as they were working on the application of robotics to agronomy. Using the more classic definition of hydroponics, cultivating produce using water (instead of soil), they worked to find a solution that would involve water, less energy and fewer square meters of space.

The Hessels created indoor fields of crops, developed mechanized fields of Styrofoam beds of lettuce plugs that are rotated over recirculated, nutrient-filled water for a period of four to five weeks. The crop beds, which are 35 meters long and 2.5 meters wide, are housed in an environmentally controlled, 40-foot container that uses artificial light, or a greenhouse that uses natural sunlight.

Because all growth takes place indoors, the lettuce greens can be grown 12 months a year. Planting, harvesting and packaging are performed by intelligent robots, monitored by a computerized control center.

“We basically supply the conditions of springtime, not summer, not winter, for 12 months a year,” explains Hessel.

The company is developing a series of growing machines for different kinds of produce, and currently sells GrowTech 2000, a standard 40-foot container that uses a specially developed fluorescent light and computers that monitor oxygen, light, carbon dioxide, humidity and temperature levels.

GrowTech 2000 offers the best solution for growers in cold climates where land and labor are relatively expensive. Another version, GrowTech 2500, was designed for climates with more available land and sunlight, using a more traditional greenhouse structure to take advantage of the natural light from the outdoors.

The company made its first European sales this year, selling two units of GrowTech to Van Dijk Nurseries Ltd., an Irish distribution company that grows, sources, ships and markets fresh fruits and vegetables to Irish, UK and European customers.

OrganiTech had already sold several units to Gush Eilat, an Eilat partnership that supplies heads of lettuce to several local hotels that were paying exorbitant costs to have lettuce trucked down from Tel Aviv. Another farm in Yardena, the Menachem Levy Farm, uses an OrganiTech installation to grow lettuce for export.

“I see it as the right option for saving on labor, energy and space,” says Tziki Levy, the farm proprietor. “The quality is very similar to that of my soil.”

The Levy farm grows only herbs and lettuce for export to Europe and the U.S., counting on the enriched soil of the Jordan Valley region to help cultivate high quality produce. Exporting 200 tons, or 200,000 kilograms of herbs and lettuce by plane each year, the Organitech solution was expensive at the outset, said Levy, but has become worthwhile over time.

At around $180,000 for a greenhouse version, and nearly double that for a container using artificial light, the hydroponic platforms can produce from 150,000 to 400,000 heads of lettuce per year, but can be an expensive proposition, admits Hessel. Then again, the system can lead to a reduction of up to 80% of the costs for heating and labor, two of the most serious costs in the greenhouse industry, according to the company’s figures.

For now, OrganiTech is focused on making sales in order to start making some profits.

Initially financed by the Technion Entrepreneur Incubator program, followed by another two years in research and development when it was funded by a series of angel investors, the company became publicly listed on the Nasdaq Stock Market when it participated in a reverse merger, receiving $3.5 million in funding.

Now, with a total $6 million invested, OrganiTech is expecting about $1 to $2 million in sales this year. The company has representatives and distributors located in Australia, China, Europe and the U.S.

“We need to sell thousands of these in order to turn a profit,” says Hessel, who is aiming the company’s marketing efforts at the growing number of supermarket produce suppliers that handle the entire process, from cultivation to distribution. “It’s easy once you get people to understand the incredible added value that this offers.”