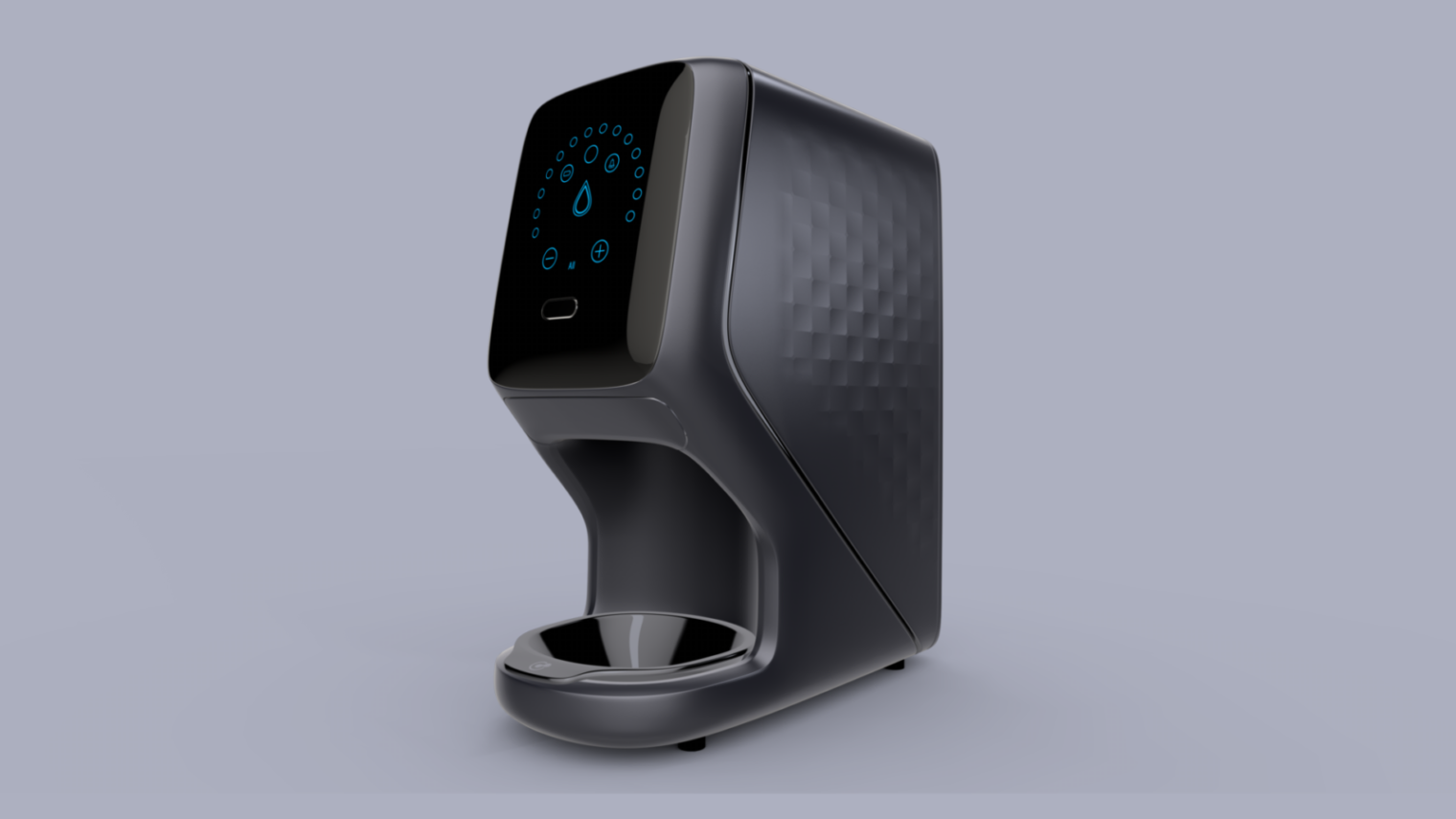

You love your Nespresso coffeemaker, the one occupying pride of place on the kitchen counter. It’s so easy – just pop in a capsule, press a button, and out comes fresh-brewed java.

Israeli startup Capsulab aims to bring that same one-click simplicity to wellness, health and beauty.

Think about your favorite skincare product. It may contain ingredients sourced from all over the world. Some are shipped from China to the United States, where the finished product is manufactured, packaged and sent to a warehouse for distribution.

That’s a lot of steps – and there’s no guarantee that the ingredients will still be fresh when the product arrives (even if it’s prior to its expiration date). Vitamin C, for instance, used in many supplements and skincare products, deteriorates with heat, movement and time.

Capsulab aims to solve the problem by putting all the ingredients for that skincare product into a single vacuum-sealed capsule.

The consumer pops the capsule into the Capsulab machine, presses a button, and the ingredients are mixed on the spot, guaranteeing a fresh, potent product.

The capsule is inserted on a tray, much like CD-ROMs of yore. The pigments and active ingredients are then mixed inside the capsule. Nothing touches the machine, so the only clean-up required is some easy wiping down.

“Think of it like a bread maker,” says Capsulab adviser Haggai Klorman, “just without the mess.”

Fresher and less waste

All this might seem more like a nice-to-have rather than a must-have.

But, as Capsulab CEO Gal Saar tells ISRAEL21c, “between 25 and 30 percent of the market is moving towards these sorts of customized products.”

The vacuum-sealed capsules don’t need additives or stabilizing agents to stay fresh, something that appeals to more and more consumers today.

“The question is, do you want less crap in the products you consume? Do you want your hair gel or supplements to be more effective? Here’s a solution,” says Klorman.

Freshness is just one of the benefits the Ramat Gan-based company offers, Saar says. There’s also less waste.

“If a big organization thinks it will sell 100 units of something, they have to produce 500 in order to make sure that in each store there’s enough product. They have to over manufacture.”

Using a device like Capsulab “won’t take that to zero, but it is getting as close as possible, since production happens at the time of consumption.”

Home manufacturing

The Covid-19 pandemic contributed to demand for Capsulab’s “Nespresso-for everything” approach.

First, “the pandemic made the industry look for contactless solutions, including home manufacturing,” Saar says.

Additionally, severe disruptions to the global supply chain have resulted in active ingredients starting to go bad as they wait to arrive at their final destination for production.

Another benefit for Capsulab is personalization. With off-the-shelf products, if you want more of a certain component, you can’t add it. With Capsulab, manufacturers can offer that option.

“You see that with Nike shoes, with espresso machines. The pharma, color cosmetics, personal care and supplement industries are all moving into personalization,” Klorman notes.

Focusing on UX

Capsulab employs 20 people and has raised $1.5 million. It is working on a handful of pilots with potential customers.

There is no shortage of Nespresso-like machines for home beauty care. L’Oréal, L’Occitane, Lancome and Shiseido all have competing devices. But there are differences.

“Those solutions take a large chemical factory and try to make it smaller,” Klorman explains. “We are the only capsule solution. We take the factory and make the entire process happen in one capsule. It’s not just a production line shrunk down in size.”

Saar adds that Capsulab’s competition started from “the chemical challenge, whereas we come from the user experience challenge. It takes less than a minute, there’s no set-up, no cleaning, no maintenance and no inventory management. It’s a one-button operation.”

And while competing solutions are meant for direct-to-consumer sales, Capsulab has a B2B model: Capsulab’s customers are manufacturers, not shoppers. Saar can even imagine a company like L’Oréal adopting Capsulab’s tech someday.

“We want to be the ‘Intel Inside’ of health and wellness products,” Klorman adds.

Personalized products

Capsulab is starting with health and wellness, but the technology’s potential applications are much broader. Saar pointed us to two recent Capsulab tests: making fresh tahini and ranch dressing.

Theoretically, Capsulab will be able to produce a single machine that handles multiple products, says Klorman, “but we’re still a startup and we need to focus on where people are banging on our doors.”

So far, that’s been the cosmetics business.

Pharmaceutical companies are also on the company’s radar. Capsulab’s ability to personalize means doctors “can change the ratio between active ingredients on a person-by-person basis,” Saar says.

This works because to control the Capsulab device, you use a connected app on your mobile.

“Since we’re enabling a digital platform, we capture behavioral data – who used what capsule at what time, what are they interested in, what doses are working,” Saar says.

The app will, like Netflix, support multiple user profiles so things don’t get mixed up.

The data collected by the device can also benefit healthcare providers.

“A prescription may be to take 10 mg of a medication for 10 days,” Klorman notes. “But the doctor doesn’t know if it was taken for the full 10 days or not. Here, it’s tracked. You put the capsule in the machine and the doctor gets feedback. If he wants to start at 20 mg and move to 10 mg later, he can do that without worrying about someone making a mistake.”

To learn more about Capsulab, click here