The world’s largest desalination plant will supply 15 percent of Israel’s household water needs.If there is something that all Middle Eastern countries can agree on, it is the need for more sources of water in their region. Water shortages, and the issue of allocating the existing resources, are a constant concern and often a source of conflict between the countries in the area.

A state-of-the-art desalination facility, the first stage of which has just begun operating at Ashkelon on Israel’s southern coastline, may, in the near future fulfils its creators’ expectations and ease the regional water wrangling.

Rain can’t be counted on in the Middle East. With inconsistent precipitation, sufficient amounts of water from the skies can’t be taken for granted every winter. Until two years ago the country’s primary natural reservoir, the Sea of Galilee, dropped alarmingly and the water situation had become quite desperate. Thankfully, two wet winters ensued and the picturesque lake filled up again. But, as American author Alice Hoffman once said: “When all is said and done, the weather and love are the two elements about which one can never be sure.”

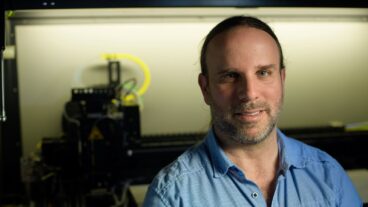

Of course today the inconsistencies of nature can be, at least in part, compensated for through technology. “You can’t look to rain as a constant,” concurs Ashkelon project technical manager Micha Taub from OTID. “But, we hope the new plant will go some way to redressing any lack of precipitation.” OTID is a joint venture company formed by IDE Technologies and OTV of the Vivendi Group. IDE and Vivendi comprise two thirds of the consortium building the plant. The third member is Dankner-Ellern Infrastructure.

Taub’s aspirations should, indeed, be commensurately addressed when the project is complete. The plant in question is a huge desalination facility that, when up and running to full capacity, will provide Israeli consumers with 100 million cubic meters of water a year. That is the equivalent of approximately 5-6 percent of national water needs.

The Ashkelon facility is part of a national Desalination Master Plan, launched by the Israeli government in 2000, designed to help address the country’s chronic water resource problems. This policy envisaged the construction of a number of seawater plants along the Mediterranean coast, producing an annual total of 400 million cubic meters of desalinated water by 2005, rising to 750 million cubic meters by 2020, mostly destined for urban consumption.

A series of logistical and other difficulties have somewhat delayed progress in Ashkelon but as it finally moves forward, Israel’s water situation should be a lot healthier within a few years.

Construction work on the South Israel Project began almost two years ago and is expected to be finished later this year. Initial production started last week and the plant is currently running at 30-40 percent capacity. “Things look very good at the moment,” says Taub. “We’ll be going for acceptance testing very soon and then we’ll go up to full production for the first plant.”

The plant is a seawater reverse osmosis (SWRO) facility which, when completed, will be the largest of its kind in the world. Just what the doctor ordered in this precipitation-challenged region. Reverse osmosis involves the use of membranes acting as an extremely fine filter to create drinkable water from salty, or otherwise contaminated, water. The salt water is placed on one side of the membrane and high pressure is applied to stop and then reverse the osmotic process.

The Ashkelon plant incorporates membrane desalination units and facilities for seawater pumping, brine removal, raw water pre-treatment and product water treatment. There are also workshops, a laboratory and other buildings, access roads and a dedicated gas turbine power station. The latter will go a long way to reducing water production costs, the bulk of which are generated by the very high level of power consumption required by the osmosis process.

“People have been working with membrane technology for some time,” Taub continues, “but costs have dropped significantly over the years as membrane production has increased. This has enabled us to achieve an unprecedented low cost of desalinated water.” Taub says the drinking water that will eventually be produced in Ashkelon will cost around 52.7 cents per cubic meter. “That is by far the lowest cost anywhere in the world. By comparison, water produced at a desalination plant we built in Cyprus costs about 80 cents per cubic meter. The Ashkelon plant is much bigger so you benefit from economy of scale.”

The eventual cost of the drinkable water was also impacted by the Israeli government’s demand for as low boron content as possible. Accordingly, the desalination facility consists of 32 reverse osmosis treatment trains, on four floors, and uses an optimized, multi-stage reverse osmosis and boron removal procedure. Achieving a high boron ion reduction was an important design consideration.

The plant designers also considered several methods of seawater intake, including utilizing the nearby power station’s cooling seawater discharge. Ultimately, in view of site constraints and hydrogeological considerations, they went for an open, submerged system with three parallel pipes, based on a configuration designed to safeguard supply and enhance operational reliability by producing non-turbulent feed water flows. The use of high-density plastic piping, which is simple to clean and relatively resistant to biological growth, will help to keep maintenance work to a minimum.

The Israeli facility also makes use of some unique applications, such as energy recovery, which have helped reduce costs. “The process requires an enormous amount of energy,” Taub explains. “You can cut costs, and save part of the energy you use, for example, by redirecting it back into the system. This process is applied elsewhere, where they manage to recycle around 85-90 percent of the energy they use for extracting brine. We managed to achieve energy recycling of 95-96 percent in that area of the process. That saves money and makes water production less expensive. We’ve also introduced other more subtle enhancements to the process. They make the difference between producing water at 80 cents a cubic meter and achieving a price of 52.7 cents per cubic meter.”

However, desalinated water is still more expensive than the celestial offering. “Rainwater is relatively cheap,” says Taub, “despite the cost of piping water to different parts of the country. Water for agricultural use is currently less than 50 cents per cubic meter, but it costs a lot more for domestic consumption because of the various processes the water undergoes and levies local authorities impose. Of course, the great benefit of desalinated water is the security it provides, that the water is always readily available. In this country it’s good to have a back up in case you get a dry winter. We?ve had quite a few of those.”

Over the years, Israelis have been involved in establishing desalination plants elsewhere around the globe, in places like Cyprus, the US and China. Now Israelis, too, will benefit from the wonders of desalination technology. Those benefits may soon also be offered to Palestinians in the Gaza Strip. “We expect to be up to full production of 100 million cubic meters of water a year by the end of the year,” says plant engineer Gustavo Kronenberg. “We have already received Prime Minister Ariel Sharon’s blessing to eventually use the plant’s full capacity of 120 million cubic meters a year.” Kronenberg continues. “Once that happens we?ll be able to provide the Palestinian Authority with 20 million cubic meters a year. We have held talks with the Palestinians and they have expressed great interest.”

With virtually limitless amounts of seawater available the new plant, and the other planned facilities, should allow Israelis and their neighbors to drink and irrigate more easily for many years to come.