On her many dives across the globe, Israeli marine biologist Shimrit Perkol-Finkel was distressed to see the ecological damage done by concrete ports, breakwaters and piers.

“These structures destroy the natural habitats, replacing natural reefs with a desert of concrete. If anything grows on it at all, it’s an invasive, harmful species,” Perkol-Finkel tells ISRAEL21c following a US road trip to promote her startup, ECOncrete of Tel Aviv, founded in 2012.

ECOncrete has developed a suite of environmentally sensitive concrete products that enhance marine life while increasing the structural stability, longevity and aesthetics of urban waterfronts and coastal structures.

The technology features a modified concrete “recipe,” a variegated texture attractive to marine life, and a 3D design to accommodate elements such as tiny holes for little fish to hide in.

ECOncrete CEO and Chief Scientist Perkol-Finkel and CTO Ido Sella earned their doctorates in zoology from Tel Aviv University and have extensive experience in marine biology and ecology.

Their startup was nurtured at the prestigious Entrepreneurship and Innovation Support Program (EISP) 8200 accelerator and won its award for best startup of 2014. By that time ECOncrete had raised $1.7 million in seed money and had three pilot projects on the go. Among these were two installations at Brooklyn Bridge Park in New York.

In 2016, ECOncrete received a grant from the Israel-U.S. Binational Industrial Research and Development (BIRD) Foundation to work with the Besser concrete company of Michigan to engineer, test and manufacture bio-enhanced concrete products.

ECOncrete has made three sales agreements with concrete precast manufacturers — in the UK, California and Austria.

Next year, the Israeli company’s products will be used in several large developments. For example, ECOncrete technologies are part of the SCAPE Team’s winning Living Breakwaters project in the Rebuild by Design competition for the New York borough of Staten Island, meant to protect the coastline with sturdy structures that encourage the growth of oyster communities.

Scaling up

The founders initially experimented with nearly 20 concrete admixtures in the Mediterranean. After choosing the best five, they did two years of controlled tests at the Red Sea; in Florida, New York and the Great Lakes in collaboration with the US National Oceanic and Atmospheric Administration; in Savannah in partnership with the Georgia Port Authority; and in several New York locations.

“We verified that ECOncrete is significantly better than what is out there today, and we published the results of our studies in peer-reviewed journals,” Perkol-Finkel says.

The company was one of seven 8200 EISP graduates at revenue stage to be chosen for a fall 2017 Business Tour to New York City and Chicago, during which Perkol-Finke met with architectural and engineering firms as well as VC funds.

Since its founding in 2011, EISP 8200 has supported some 130 startups that have raised a total of $400 million from investors.

“We have opened a Series A fundraising round,” reports Perkol-Finkel. “It’s not a simple field in which to raise money, but I received a lot of very positive feedback as there is more awareness of environmental issues in coastal construction.”

An investment of between $2 million and $3 million will be necessary for ECOncrete to scale up in order to compete for mega installations in countries including the United States, where there is growing demand for mitigating environmental damage on the coastlines.

With a staff of nine in Tel Aviv and two in the United States, ECOncrete runs a small in-house concrete laboratory where concrete specialists and geologists test the company’s products for durability, strength and safety in simulated conditions specific to different bodies of water.

“The model we’re working on is providing the admixture design and the mold system. We don’t produce the concrete; we always work with local manufacturers to do that,” says Perkol-Finkel.

“So we don’t need a huge company. We can work with companies that have a large sales force. We already have a New York subsidiary established in 2016, and once we go to China, we will have some kind of subsidiary there as well.”

Perkol-Finkel explains that previous attempts to mitigate the damaging effects of concrete coastal structures focused on creating artificial reefs in the vicinity of the structures.

“But that’s another manmade footprint on the seabed, even if it has some ecological value. Our concept was to take all the infrastructure already built and use it as a scaffold for a reef, something nobody’s done before now.”

ECOncrete’s products can be used to improve and maintain existing structures or to build new ones.

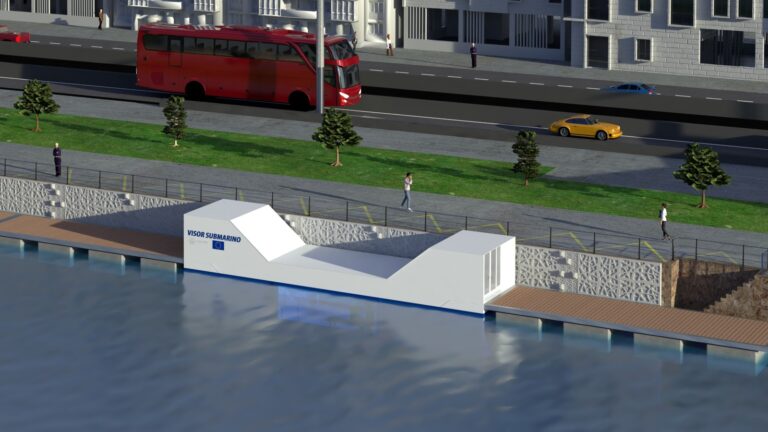

Last September, Perkol-Finkel won the GreenPitch competition organized by TheHive by Gvahim in partnership with Switchmed, a EU program supporting green entrepreneurship in the Mediterranean area.

She and/or Sella are traveling to global events including the Union for the Mediterranean’s Blue Economy Stakeholders Conference in Naples, Italy; Cleantech Forum San Francisco 2018 and an international summit at the Florida Climate Change Institute of the University of Florida.

For more information, click here