What do the Ford Motor Company, Johnson & Johnson, Eastman Kodak and BBC have in common? These household names, and many other major companies, have discovered a new way of thinking – promoting creativity to develop new products using a unique methodology developed by a team of Israelis.

The methodology is named “Systematic Inventive Thinking,” and Johnson & Johnson’s Ethicon division’s Director of Marketing Mastery was so inspired by this unique Israeli method of innovation that it led to the complete redesigning of an anaesthetic device that had already been designed and engineered.

“Systematic Inventive Thinking” (S.I.T) is the name of both the company and the method it has developed for enhancing innovation and creativity in organizations by the use of templates, or to use the modern term, patterns of thinking. The methodology is based on the pioneering work of a Russian engineer, Genrich Altschuler, created while he was a political prisoner in Stalin’s Russia.

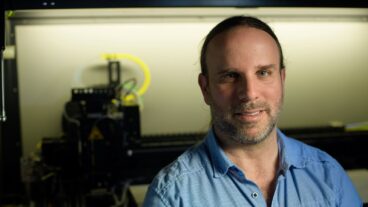

The system was refined in Israel by two researchers, Dr Jacob Goldenberg and Dr. Roni Horowitz. They took Altschuler’s original idea, which was used for solving problems in which issues were simply defined in terms of cost and product reliability and adapted it for use in designing new products.

Horowitz discovered it when he saw an advertisement about a course in inventive thinking. He has recently completed his studies in aeronautical engineering while serving in the Israel Air Force, and decided to enroll in the class to supplement his education.

“I said to myself either its absolute rubbish or there could be something in it,” he recalls.

The teacher was a new immigrant from the Soviet Union, Gennady Filkowsky, who was one of Altschuler’s pupils. Horowitz immediately saw the potential of the method, became very enthusiastic, and then convinced Goldenberg, who had served in the airforce with him and also studied aeronautics, to complete the course as well.

In 1990, at the same time that Horowitz completed his military service, Filkowsky left the country. Horowitz saw this as an opportunity and began to conduct the courses in inventive thinking himself. Soon afterwards, he commenced his doctoral studies, and devoted his thesis to inventive thinking, continuing to teach courses while working on his thesis.

The SIT company was established shortly afterwards and was the brainchild of Chaim Peres, from one of the major advertising agencies he had worked with.

The company, based in Tel Aviv, is privately owned, and employs more than twenty full time staff, with subsidiaries in Sweden and Germany, and associates in other countries. From the beginning, the name of the method was also chosen as the company name in order to emphasize that the method is the core of the business.

S.I.T is applied in four main fields: Enhancing Organizational Creativity, Problem Solving, New Product Development and Advertising.

Among the companies in Israel using the S.I.T system are Coca Cola Israel, Elite Foods, Discount Bank and the Israel Export Institute

The first major US corporation to hire S.I.T. was the Ford Motor Company. Horowitz went to the USA and conducted a 40 hour course at their headquarters. They subsequently sent four people to Israel to complete a training course. Since then, Ford have trained over a thousand of their employees in the method after the powerful combination of the method and the methodology in running the workshops brought results.

What attracts these large entities to an Israeli company for training in innovation and product development, as well as the methodology in running the workshops? Horowitz pointed out that as a result of publishing a book on the method, which he co-authored with Goldenberg, as well having several articles published in the Wall Street Journal and Harvard Business Review, companies saw the S.I.T. method as very attractive, and, having heard about other companies success in using the method hired S.I.T.

Amnon Levav, CEO of the company, explained that when clients come to S.I.T. they usually want to expand an existing product line or to fill a gap where a product does not exist.

S.I.T’s philosophy is that while creativity involves new ways of thinking, people need a framework for creative thinking and their patterns provide that framework for analytical thinking that can be applied to various products. It does not force changes in thinking, it simply offers a set of instructions that help set the creative thinking in motion.

S.I.T stresses that the process is not meant to replace a company’s product development program entirely, or to replace individuals’ creative abilities. It is designed merely to enable companies to re-examine their products, and by imposing a discipline on their thinking, can help a company hit the hot spot in their marketing.

It is commonly, and perhaps mistakenly, believed that the best source of new ideas is the market. But traditionally customers are notorious in opting for minor changes in a product often resulting in poor sales because they are so fixed in their buying habits that it would take more of an innovative and dramatic change in a product to inspire them to change their habits.

How then can product developers succeed in being on-target with a product? By using an alternative source – S.I.T’s unique approach to idea creation and innovation, existing products are used as a basis for new ideas.

Five patterns of thinking are used in the S.I.T. methodology. One is “subtraction,” where, rather than adding on features, the opposite approach is adopted. Philips Consumer Electronics decided to employ this approach. They were having difficulty in finding ways of enhancing their DVD players, and discovered that by replacing all the control buttons with one single button to control the most important functions, they communicated simplicity resulting in the company?s award winning “Slimline-Q” series of DVD players.

Another pattern is “division,” where components of a system are divided and rearranged. By dividing an existing product into its component parts companies can gain a different perspective, which could lead to a reconfiguration of the product in a different form. A classic example is the old hi-fi system, originally housed in one cabinet, giving way to modular speakers, tuners, amplifiers that allow the end user to customize his or her system.

Mr. Drew Boyd, Director of Marketing Mastery at J&J’s Ethicon Endo Surgery Division explained how the S.I.T method induced them to revamp one of their products just before prototyping – a new type of anaesthesia device that had already been designed and engineered.

The development team was invited to a workshop and told that they should use the S.I.T tools to come up with innovative ideas. Their initial response was “We’ve already designed this.”

However, by 11 a.m. the same day, they were convinced there was great potential for improvement. This later led to a redesign of the entire system. It set the project back two years, but with the method as a starting point, a far superior system was developed. The method made them realize that there are many new ways of looking at a product. Boyd commented “The tools are very good at breaking rigidity in thinking”.

Asked how the methodology differs from traditional methods of thinking, Yoni Stern, Manager of US Operations at S.I.T., explained that one of the most traditional methods of coming up with new ideas is brainstorming, where a group of people think of as many ideas as possible and are then asked to build on them. The rule is that no idea can be judged — judgment is suspended in favor of divergence. The result is often a large number of ideas that have not gone through any filtering process. The main problem in dealing with large lists is that in the real business world, executives don’t have time to review and judge them afterwards to see which of the ideas are relevant.

The S.I.T method then has filters built into the process. When an idea is raised it has to be judged according to its market potential and feasibility, and only if it passes the various filters is it added to the list, to be examined more closely. Stern explains that a five-day project typically yields 60 – 80 ideas, of which four to eight will probably be developed further into concepts. This is a manageable number that can be reviewed by the team on the last day and developed into something more useable, including action items for implementation.

Stern notes, “We’ve been working with Nestle in Prague, Hungary, Switzerland and Israel. Because the company is so diversified it is not easy to see organizational changes but we can see some very specific results. We worked with them mainly on their products, and occasionally on their marketing communications, but primarily product development, and there are specific results to show for that. Our goal is to influence the way they think and the way they do business, and we believe that we have achieved some success.”