XJet of Rehovot has opened the world’s largest metal and ceramic additive manufacturing (AM) center with an investment of more than $10 million.

The Israeli company, which has developed innovative nanotechnology for 3D printing in metal and ceramic materials, aims to modernize manufacturing processes in the automotive, medical, dental, aviation, aerospace and robotics industries.

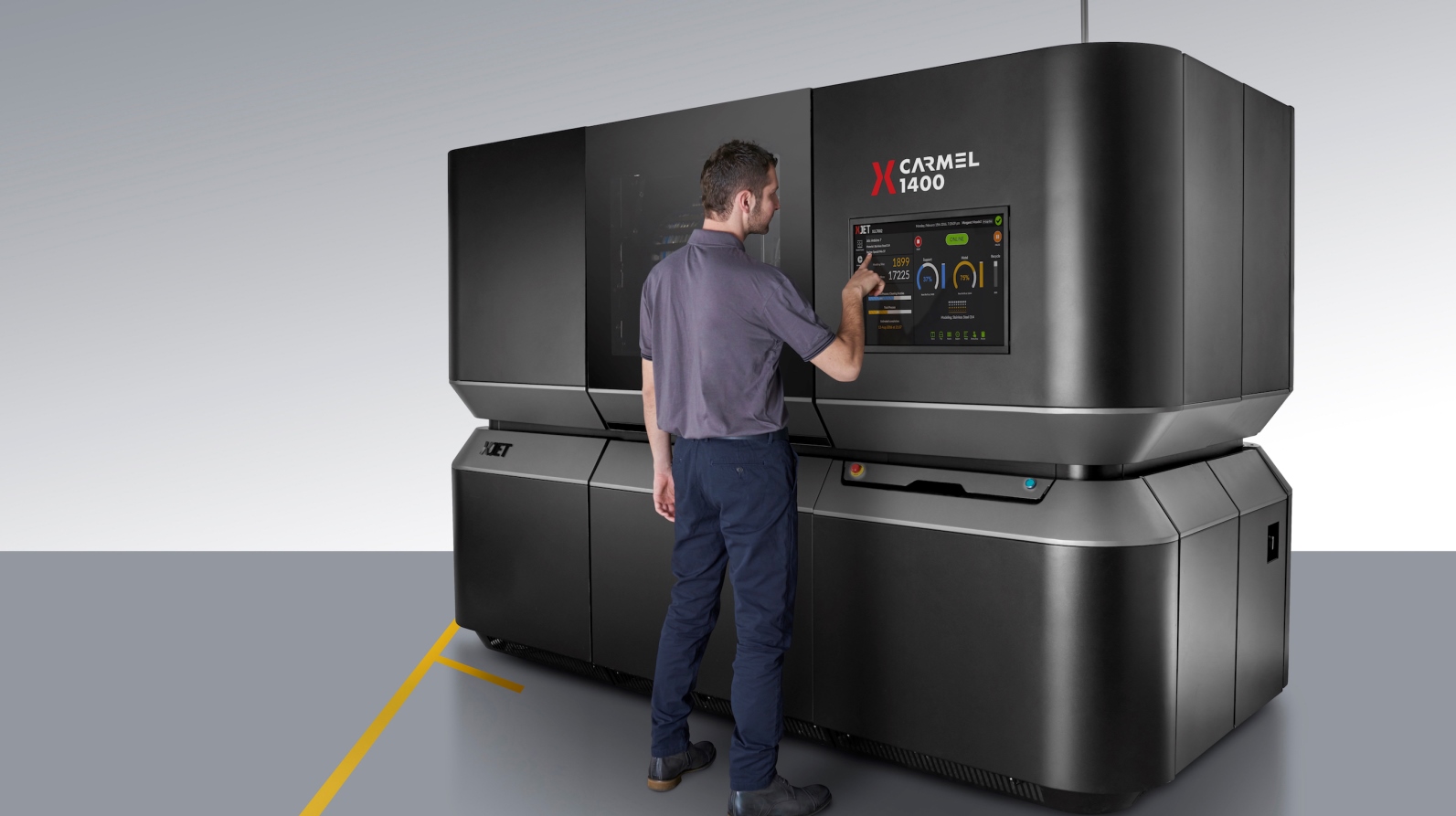

The center will enable the development of specialized applications in cooperation with large companies in Europe, North America and Asia, and support XJet’s efforts to develop and expand the variety of metal and ceramic materials used by the company’s Carmel AM systems, and expand the range of supported AM applications.

XJet’s innovative NanoParticle Jetting technology features liquid suspensions containing solid nanoparticles of selected build and support materials that are jetted onto the build tray to “print” complex and/or unique metal and ceramic parts.

XJet reports $10 million worth of contracts for the sale of printing systems to customers in Europe, the US and Israel. Frost & Sullivan recently awarded XJet a 2018 Best Practices Award for Technology Innovation.

XJet also announced that it is in the midst of a significant fundraising round, intensive personnel recruitment and establishment of a global distribution network.

“A recent market survey indicates that while the AM market is growing at an annual rate of about 25%, metal AM is growing at a much higher rate of about 80%. Metal AM has been implemented by a large number of Fortune 100 companies, and the market is ripe for high-quality solutions such as those provided by XJet,” said Hanan Gothait, XJet CEO.

Fighting for Israel's truth

We cover what makes life in Israel so special — it's people. A non-profit organization, ISRAEL21c's team of journalists are committed to telling stories that humanize Israelis and show their positive impact on our world. You can bring these stories to life by making a donation of $6/month.