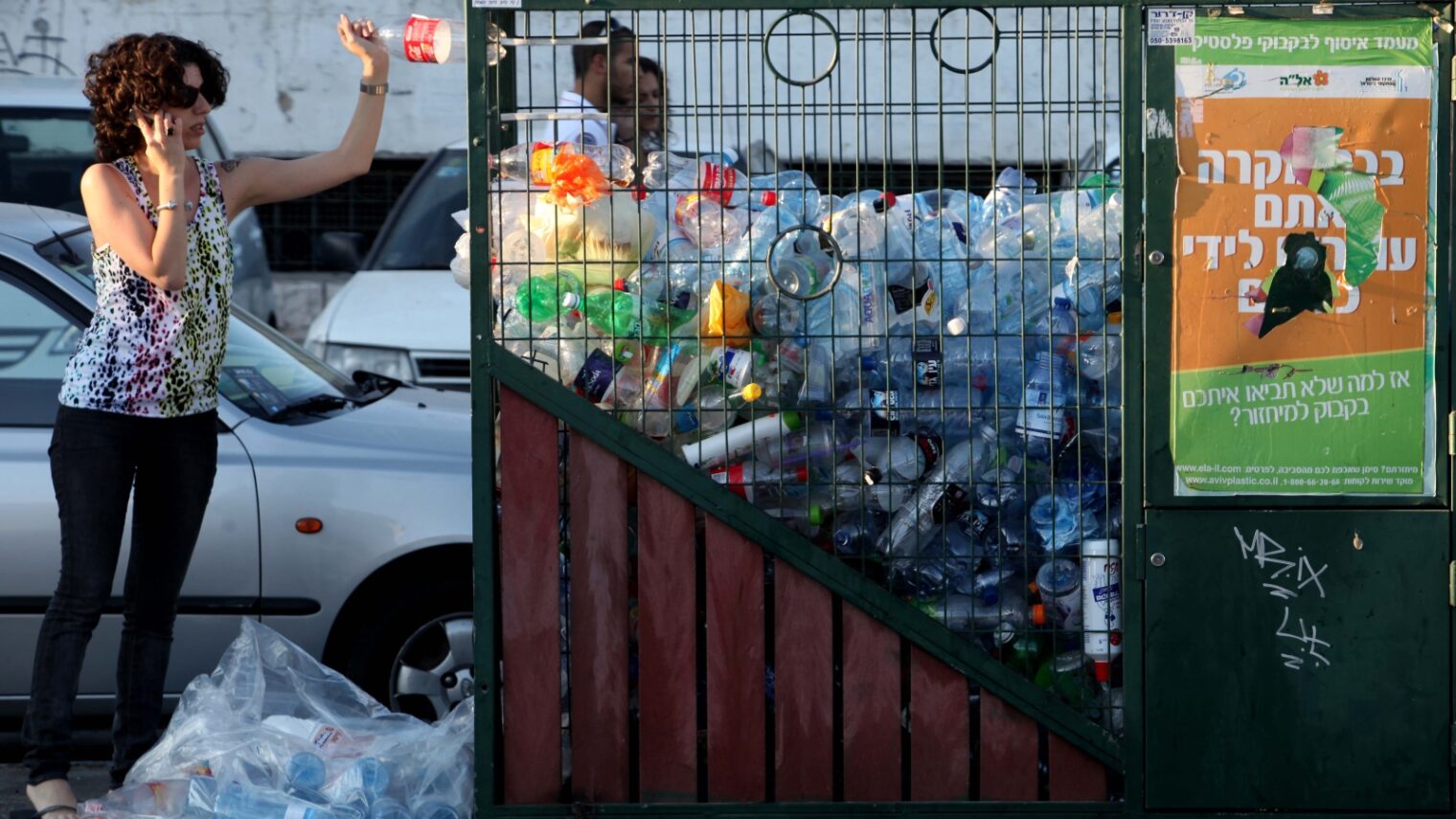

Plastic waste is one of the most recognized environmental issues today.

From global recycling failures, to ocean pollution and trying to do away with single-use items, it all boils down to the same question: What do we do with the hundreds of millions of tons of plastics still manufactured every year, and worse, the billions that have accumulated in the landfills and oceans all over the planet?

An Israeli-led company offers a new industrial process that transforms used plastic into new source materials for other manufacturers.

From vision to reality

Clariter is an international company with a home base in Israel. Its patented technology offers a potential opportunity to overcome the plastic waste challenge by turning it into a new value chain independent of fossil fuels and their emissions.

The technology further offers an alternative to traditional recycling, which converts plastics into other plastics (mechanically) or to fuel – neither is ideal, environmentally speaking.

Clariter was established in 2003 by Israeli entrepreneur Ran Sharon, following a chance encounter with Prof. Andrzej Bylicki, an elderly Polish chemist. Bylicki’s research led Sharon to pursue an idea about converting post-industrial plastics into wax, solvents and oil.

Over the next two years, they improved the idea and developed the proof-of-concept for a process that can upcycle most types of plastic. In 2006, Clariter opened a pilot plant in Gliwice, Poland.

Over the years, with a total investment of some €35 million (about $38 million) – mostly from private sources – the company expanded its R&D center in Poland.

Backed by a development bank, Clariter recently unveiled a manufacturing plant in the South African town of East London. During this period, the company registered patents for their processes.

The South African plant is a demonstration and training site, aimed at scaling up the R&D facility to treat some 1,000 tons of plastic waste per year (mainly polyethylene, polypropylene and polystyrene) and further test various industrial variables.

The company currently produces materials for products such as candles, shoe care, lubricants, coatings, and cleaning solutions. This range might be expanded due to increased capacity or regulatory approvals.

Plastic Candles

So how does it work? First, the plastic is thermally “cracked” into liquid, which is then refined into two types of hydrocarbons.

Subsequently, the hydrocarbons are distilled and either separated or mixed into the desired output: oil, solvents or wax.

The company maintains that its end products are of high-quality and pure. For example, the oil is clear, odorless and nontoxic.

Clariter’s solution might have the potential to tackle the plastic waste problem, reduce the dependency on newly sourced fossil fuels, and provide materials for a local manufacturing ecosystem in the community (a “ClariCluster”). But is Clariter itself sustainable?

In an email interview, the company’s R&D Manager Daria Frączak explains that “Clariter’s process has two byproducts — char and synthetic gas, both of which could be reused: the char by asphalt producers, and the gas by the plant’s own energy demand.

“The results of a Life Cycle Assessment we conducted show that currently, Clariter’s CO2 footprint is preferable to incineration (even including energy recovery), pyrolysis (thermal decomposition), and landfilling,” Frączak says.

She adds that “the advantages of using thermal cracking are found in the hydro-refining of our process that we use in combination with this cracking method. The major advantage of Clariter’s process compared to other polyolefin (one of the most widely used types of plastics) chemical recyclers is that we create high-value final products in one plant without the need for petrochemical plants.”

Future plans

With some 80 employees in three continents, the company wants to establish a full-scale plant, possibly in Israel.

“In Israel,” explains Clariter’s VP of Business development, Yariv Eldar, “as in other geographies, the facility needs a steady stream of plastic waste at a required quality, quantity, availability and price. In addition, site permits (both environmental and construction), investments, and a possibility to sell the products is also needed. Help from all relevant authorities would be a great step toward the realization of a Clariter facility that will help to clean up Israel’s plastic waste.”

The new full-scale plants should be able to handle some 60,000 tons of plastic annually. At this scale, which potentially results in some 50,000 tons of products, the plant would also be profitable.

The company plans to construct five additional plants by 2028, perhaps in a joint venture arrangement. Clariter expects to build these factories in urban settings, given their low environmental footprint.

Another potential avenue for growth is landfill recovery programs. Eldar says one such partnership is under discussion in Poland, “where one landfill contains about 1.2 billion cubic meters of material, with 25 meters above and 20 meters below ground, which should supply a steady stream of plastic waste to our process for many years to come.”

For more information, click here

Ran Ben-Michael writes for the ZAVIT Science and Environment News Agency