A teenage girl with a mysterious malady motivated the June 2015 establishment of Israeli smart packaging innovator Water.io. Her father and two of his friends cofounded the company after the mystery was solved.

“The medical problem that plagued his daughter, we were shocked to discover, was easily resolved by simply drinking more water. So we tried to figure out why people forget to drink and we found out it’s a major problem,” says serial entrepreneur Yoav Hoshen, a Water.io cofounder and vice president of business development.

“We saw that in the US alone dehydration results in at least 1.5 million outpatient visits, 200,000 hospitalizations, and 300 deaths per year. Yet billions of people drink water every day from disposable water bottles. We wondered if these bottles somehow could measure how much people are drinking and provide personalized reminders on the cap closure. That’s how we started.”

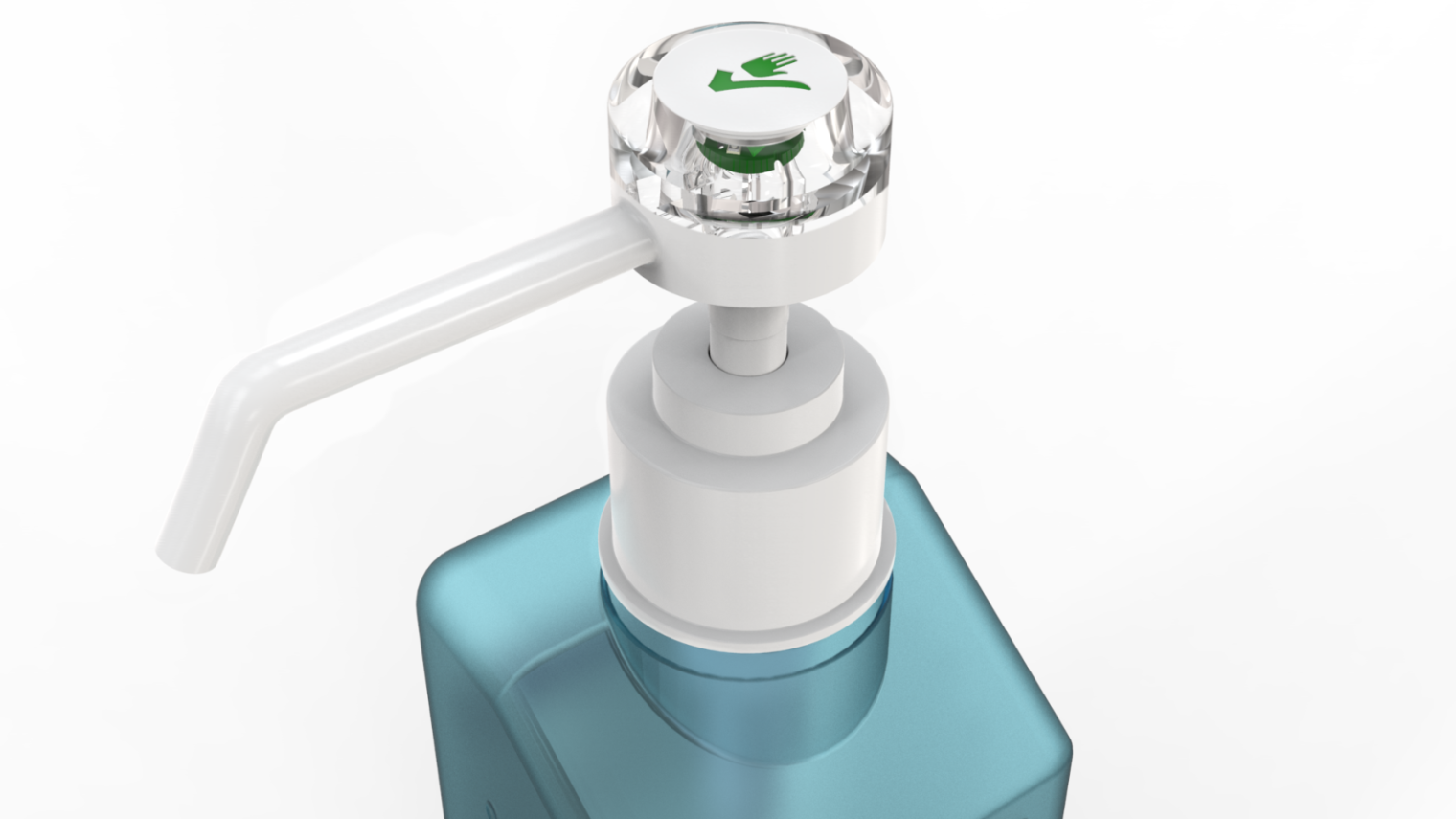

The first product, “Reminder,” is a patented IoT smart cap for disposable water bottles available to manufacturers on a B2B2C model. Reminder blinks, vibrates or sounds an alarm according to preset reminders.

The IoT sensor, built in or attached to existing caps, automatically adjusts reminders based on actual bottle usage so people aren’t alerted to drink if they’ve already done so.

The Reminder smart cap is now used or tested by about a dozen customers including Israel’s Mey Eden (part of the international Eden Springs brand), as well an Australia-New Zealand packaging leader and others Hoshen can’t mention by name.

“Connected,” a second Water.io version in the late pilot stage, works with a smartphone and factors in customers’ weight, age and gender, plus weather and activity level, to determine when and how much each user should drink.

Any liquid, powder, pill

Water.io has pilots in progress with large international consumer packaged goods brands beyond the beverage vertical. The platform was expanded into a unique line of smart caps to transform any bottle into a smart bottle – no matter if contains a liquid, powder, pill or capsule that gets poured, pumped or sprayed.

“We started with smart hydration but we solve many additional problems,” Hoshen tells ISRAEL21c. “We’re the only company with a commercially available disposable IoT smart-cap solution for the pharma, beauty, cleaning and additional industries, having already hundreds of thousands of smart caps in the market.”

For instance: A smart cap on your sunscreen bottle could send re-application reminders based on how much UV radiation it measures in the air. Foods that must be kept at a certain temperature could automatically be monitored by a Water.io cap.

The smart caps, which last up to a year before needing replacement, also can connect the package to a smartphone or any other communication hub. Via a mobile app, brand dashboard and cloud server, consumer packaged goods and pharmaceutical brands could interact with purchasers and gather insights to improve their products, brand loyalty and bottom line.

In fact, many companies incorporating Water.io smart caps do not plan to pass along the extra cost to consumers, says Hoshen. By revealing how and where their products are being used, the caps provide manufacturers a new way to increase revenues and margins via a direct-to-consumer business model.

Without gathering personal identity info, manufacturers can use this data to send discount offers, loyalty points, or suggestions of more efficient ways to use their products based on usage and location data they see on their Water.io dashboard.

Frost & Sullivan recognized Water.io with its 2018 Global Entrepreneurial Company of the Year Award. “Water.io’s innovative sensor-enhanced caps and closures have given rise to the entirely new concept of the Internet of Packaging,” F&S judges wrote, calling the platform “groundbreaking.”

Automatic reorder feature

Currently, an automatic reorder feature is being piloted for products such as laundry detergent, food and personal care products from top consumer packaged goods brands, Hoshen says.

The bottles carry a label explaining that you can choose to subscribe to a reorder service by downloading an app that gets data from the smart cap. When the contents dip to 10 percent, subscribers will be sent a refill pouch for replenishing the existing bottle. A side benefit is reducing the amount of hard plastic packaging that gets thrown away.

Additional reorder and pharma products are in development at Water.io.

“All the solutions we build must pass two major obstacles,” says Hoshen. “First, they must not change the way the consumer uses the product; and second, they must work in such a way that manufacturers don’t need to change their production lines.

“The cap simply provides additional value for the consumer without additional cost, helps save the environment, and creates a channel for direct engagement. We turn usage into valuable data for consumer and manufacturer.”

The smart caps are made in Asia by subcontractors, while the software and data analysis is done at Water.io’s offices in Rehovot Science Park.

“We work with some of the biggest caps-and-closures companies in world as our strategic partners,” says Hoshen. “Eventually we will not be manufacturing them at all, but will sell a license to the manufacturers. We will always provide the services based on the data.”

The company was bootstrapped in its first year and then raised seed money from private investors in Israel and North America. A $4 million funding round is now being finalized.

For more information, click here