Plastics, sheep gut, silk and metal wire: the materials that doctors have used to stitch wounds together on the battlefield and in the clinic have changed over time, but none of the solutions are perfect. They take time to apply, leave scars, and a body vulnerable to infection as the wound heals.

Researchers from the Technion – Israel Institute of Technology in Haifa, have “spun” together something brand new. They’ve created a kind of fiber, which can be applied like a dressing, to help a body stitch together wounds.

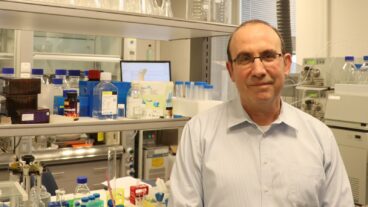

Based on a protein found in cow’s blood, it can be used like a second skin to heal the type of external wounds created after a C-section, and also internally on abdominal wounds and those created during heart operations, says its inventor Prof. Eyal Zussmann, from the Department of Mechanical Engineering at the Technion.

Less scarring, less infection

Using the protein, bovine serum albumin, Zussmann has created the fibers from tools in nanotechnology, through a technique called electrospinning. The material he has developed into thread form can be formed into a patch that could be used extensively in medical applications.

Zussmann’s solution is closely related to the human protein, human serum albumin, an abundant protein in the body. The new material is such a close match that the human body cannot tell the difference between its own and the cow protein, he explains. This means that wounds will heal better, with less inflammation.

With the bovine serum already being produced on a commercial scale, it might not take long before bovine serum fibers are used as a standard in hospitals around the world. Currently researchers from the Technion and Tel Aviv University are jointly conducting experiments to realize the commercial potential of this new technology.

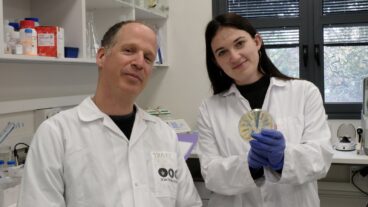

By connecting a needle-like spinneret to a power source, the researchers were able to release a charged liquid made from bovine serum albumin that gets drawn toward a collector plate.

Stretching out to the collector plate, some of the molecules in the bovine serum albumin hold themselves together, forming a solid thread. The scientists made this possible by adding a chemical called beta-mercaptoethanol, which allows fibers to be spun into long and even threads, useful for both suture threads, and conventional wound dressing materials.

A tailored solution

“The advantage of working with nano-technology or nano-fibers is the diameter at the nanoscale provides a great surface area, a large square meter surface per gram of material,” Zussmann tells ISRAEL21c. “This is important for adhesion,” he adds, as greater surface area means a stronger potential for contact on the wound surface.

“The scale of the nanofibre is similar to our extracellular matrix, our tissues, our body’s fibers such as collagen, which makes up part of our tissues. The typical size of the fibers [we created], are similar to those in our bodies. Cells sit very good on these new fibers,” Zussmann adds.

Potential applications for this biodegradable solution are limitless in the medical field. “It’s like a skin graft,” says Zussmann, “It can be tailored based on the application.”