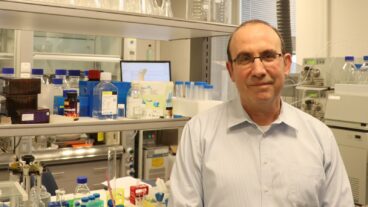

‘My dream was to develop a self-sterilizing textile,’ says Jeffrey Gabbay, founder and CEO of Cupron.

To accomplish goals as diverse as preventing the transmission of the avian flu virus to curing athlete’s foot, Cupron, a small American company with a research base in Israel, has developed a valuable new technology out of a very old element – copper oxide.

Copper’s anti-microbial properties have been known for more than 5,000 years. Ancient Egyptians used copper pipes to transport water safe of parasites; shipbuilders used copper to keep algae from encrusting ships, and French vintners use copper to fight fungus on grapevines.

Cupron decided to take the uses one step further and introduce copper into clothing and textiles, that, according to the company, will lead to healthier living.

“My dream was to develop a self-sterilizing textile,” says Jeffrey Gabbay, founder and CEO of the company, who has a background in textile and chemical engineering. He and his researchers have put together what is considered to be the widest spectrum anti-microbial technology known today. Based on copper oxides, Cupron’s state-of-the-art technology is incorporated into special yarns and fibers that present antibacterial, antiviral, and anti-fungal properties.

“Copper oxide is a very active compound,” Gabbay told ISRAEL21c. “It is very hard to work with. Most people work with elemental silver as it is effective against bacteria and easy to work with. The problem is that silver oxidizes and it has little effect on odor and viruses. Copper oxide is extremely effective in these fields. We invested in copper and have made it easy to work with.”

Cupron’s manufacturing technology binds its proprietary copper compound to textile fibers, non-woven fabrics, paper, latex and other polymeric products. The range of products that stand to benefit from the technology include healthcare textiles (curtains, gowns, uniforms, towels, catheters, gloves and gauze), anti-microbial air filters, anti-dust mite mattress covers (which reduce mite-related allergies), and warfare protective clothing, among others.

The research and development component for this project was launched 10 years ago in Israel. Today, there is a small 500-square-meter research plant in the city of Beit Shemesh, just outside of Jerusalem, and a main office in North Carolina. The company also has agents in England, Germany, Italy, France, and Turkey.

“We want to be a North American company, a European company and an Asian company,” says Gabbay. Cupron sends its chemistry innovations to an associate partner in Georgia and from there the chemistry is shipped to polyester manufacturers.

“We don’t need to own a factory,” explains the American-Israeli who splits his time between Jerusalem and Greensboro. “There is so much production out there. We will supply a lot of jobs to the industry but don’t actually need a big factory. You could say we jumped on a moving train.”

Earlier this year Gloves2Go, a specialty glove manufacturer in the US, announced cooperation with Cupron. “Gloves, incorporating the Cupron technology, will alter the safety conscious landscape in food handling, food processing, and healthcare,” said Joseph D. McGarry, President and CEO of Gloves2Go and a 30-year healthcare industry executive, in a press release.

“We thought our gloves were novel to the market until we learned about the Cupron technology. It’s far superior to anything out there including ours. Consumers are inundated with antibacterial and antimicrobial products, but the new gloves offer special antiviral efficacy in the face of the avian flu scare and other viral contaminations,” said McGarry.

He was not the only one impressed with Cupron’s technologies. Gabbay interrupts the interview to joyfully point out that Cupron just received notice that it is the recipient of this year’s Frost & Sullivan Best Practices award for technological innovations in an industry.

“It’s a nice thing to get the acknowledgment,” says Gabbay. “We know we’re the innovators of the year. Our hope now is to have an impact on both the textiles and the health-care industry. It is gratifying to know that we have contributed to solving the conundrum of anti-microbial activity in textiles.”

Cupron is also working with Renfro Corporation, one of the US’s largest manufacturers of socks, to offer products containing copper oxide. “We have socks that can cure athlete’s foot,” says Gabbay, who is fluent in Arabic, Hebrew, Italian and English. “The US Marines already use them. Because soldiers in combat may not be able to change their socks, socks with copper oxide help them avoid or cure athlete’s foot.”

Cupron also has ‘medical socks’ which can aid millions of diabetics who often develop foot infections as a result of their disease. “Diabetics have problems with their feet. If they wear our socks, we will assist in making sure the infections don’t occur and in case of existing wounds, we will promote their healing,” he says.

Cupron is especially interested in helping the health services industry. Gabbay says they have developed surgical masks that look like the disposable ones but have active ingredients that offer preventative measures against SARS, avian flu, and other viruses. “If and when the virus enters the mask, our mask will deactivate the virus,” he says.

The copper-impregnated fibers and polyester products are also used in bed sheets, pillow covers, and gowns and could reduce the high rate of deadly infections. The Herzog Hospital in Jerusalem is now preparing to test Cupron treated fabrics.

The New York Times has reported that as many as 100,000 patients die in American hospitals each year as a result of such infections. Hospitals in the UK, Ireland and elsewhere are experiencing the same crisis.

“We believe we’re going to impact hospital-acquired infections. We have identified what we believe to be an important method of transmission of bacteria,” says Gabbay. “When sheets and pillowcases are changed in hospitals there are 60 times more bacteria in the air than you have at home.

“Copper oxide shortens the life of germs, viruses, fungi and dust mites, and it inhibits their reproduction. This could make a real impact in reversing the current health crisis – the unacceptably high number of patients who die or suffer lasting injury because of infections contracted in hospitals.”

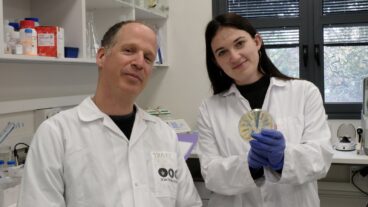

Cupron has its own viral labs in Rehovot where testing is done. The National Institutes of Health (in the US) has also tested its data. Yet even with positive results, Cupron is finding it difficult to persuade health officials that it knows what it’s doing. “We are now working on finding ways to protect people from the avian virus through prevention,” says Gabbay. “But people don’t believe what they’re seeing.”

He notes that some of Cupron’s future offerings could include treated underwear that would help women avoid yeast infections, bristles for toothbrushes, diapers to avoid diaper rash, filters for the machines that pump blood during heart operations, and filters for the ventilation systems in airplanes and buildings where air laden with germs and viruses are re-circulated.

Gabbay points out that copper oxide helps with skin renewal. He says someone who sleeps on a copper-impregnated pillowcase can “reduce wrinkles and get rid of crow’s feet.” Cupron is currently in talks with three leading cosmetic companies to commercialize its products.

Moreover, Cupron is a “green” company, meaning it recycles all of its water, chemistry and waste products. “We are committed to improving the quality of life of people all over the world,” says Gabbay.

“Our goal is to save lives. That’s really what we’re about,” he concludes. “We are going to make people’s quality of life better.”