Of all the hurdles to broad implementation of solar power across the world, one of the highest is cost. The most mainstream type of solar cell is photovoltaic (PV), made from expensive silicon wafers and silver paste.

Inventing a way to reduce the cost was a challenge taken on with relish by an Israeli quartet of semiconductor and optical technologies veterans. Their six-year-old company, Utilight, has developed a revolutionary technology for economical 3D laser printing of PV cells.

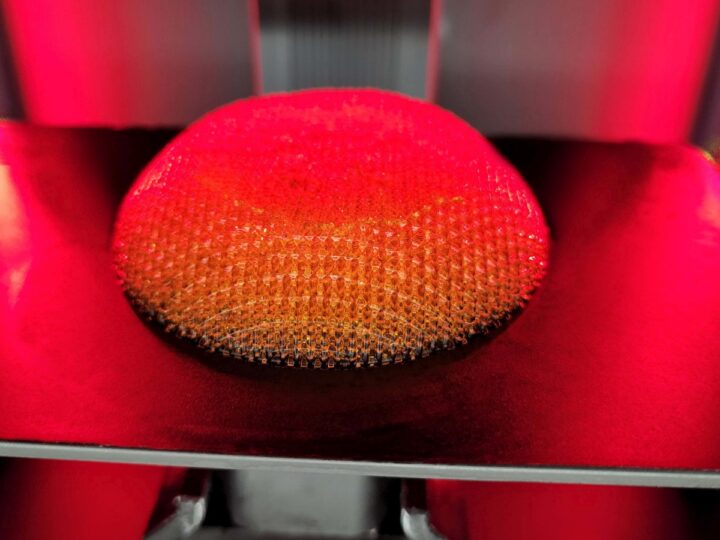

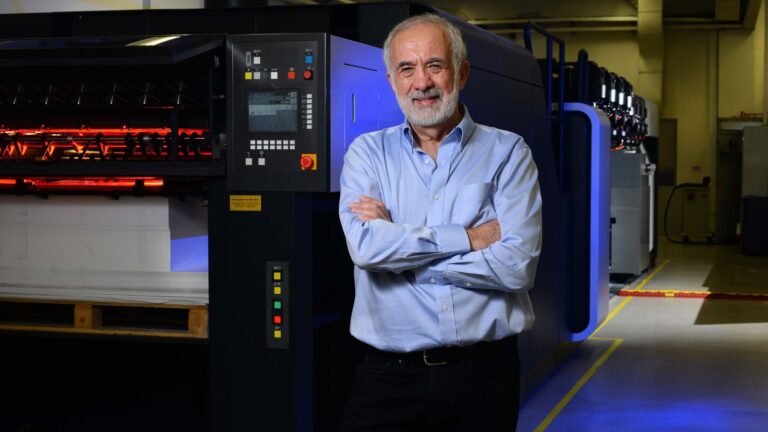

Solar cells made with Utilight’s patented PTP (Pattern Transfer Printing) method not only are priced realistically for mass manufacturing, but also are more efficient than conventionally made cells, says cofounder and CEO Giora Dishon, who holds a doctorate in material science.

This win-win product is now being tested by leading solar-cell manufacturers in China and Taiwan through a strategic partnership with Utilight.

“We are in the final stages of developing a production-ready system we can take to customers in the industry to improve solar-cell efficiency and reduce their cost,” Dishon tells ISRAEL21c. “You see solar cells on rooftops and power parks everywhere, and our technology can be used to manufacture all of them.”

Though there are other startups in Europe and North America attempting to increase efficiency and reduce costs of making of PV cells, Dishon emphasizes that Utilight’s PTP is uniquely designed to be retrofitted into existing manufacturing lines. With no capital expenditure aside from the printer, the estimated return on investment is an unusually fast six months, he claims.

“How much we save the producers is key, and in this market the only competition is conventional screen printing,” says Dishon.

“We do that by improving the efficiency of the solar cells and reducing roughly by half the amount of silver paste used to build them. This is significant in saving money and conserving natural resources.”

Rather than look for different materials to produce the PV cells, Utilight’s founders decided to stay with the industry standard, silicon and silver.

“There are different ways to make solar cells and each has its own costs per watt,” Dishon says. Assimilating PTP into the conventional production process seemed the most prudent business decision because it will be faster to market, he adds.

Future customers lined up

Founded in June 2009 by Dishon with physicists Amir Noy, Michael Matusovsky and Moshe Finarov, Utilight combined the forces of these experienced entrepreneurs “because we wanted to innovate something new and also wanted to bring value to the renewable energy field,” says Dishon.

He and Finarov previously founded and headed another company, Nova Measuring Instruments, still going strong after 22 years in Rehovot.

“For the first three years, Utilight was a true ‘garage’ operation with a small lab in a basement where we developed and improved the laser 3D printing process for solar cells,” says Dishon.

A feasibility study was financed by angel investors and R&D grants from the Israeli Office of the Chief Scientist of the Ministry of Economy.

“In August 2012, after successfully accomplishing the feasibility study and signing collaboration agreements with two major PV manufacturers in Germany and China, we received investments from three venture funds – led by the venture arm of Bosch — towards the development of commercial products for the solar PV industry,” Dishon explains.

The company now is located in the industrial zone of Yavneh, south of Tel Aviv. Pending the results of the pilots in China and Taiwan, Utilight will be ready to start marketing the product worldwide. It is already in discussions with potential customers to retrofit some 500 production lines in China and 70 in Taiwan, the two countries with the largest market share (80%) in PV cell production.

PV magazine included Utilight in its ranking of the top 50 new PV technologies last April. Dishon notes that the PTP method could be applied to manufacturing advanced electronic packaging as well.

“What we have is a great invention; I would call it revolutionary,” Dishon says. “We can take some credit for the fact that we are all old-timers in equipment and entrepreneurship and knew what we needed to do to bring a new technology to a mainstream high volume PV production.”

For more information, click here.