Oil spills are a fact of life, along with their negative environmental impacts. Large ships, ports, rigs and even cruise ships are always at risk of accidentally creating the next major oil catastrophe.

HARBO Technologies is an Israeli company with an innovative cleanup product that could save companies billions of dollars and save our environment, too.

The company has created a lightweight, easily deployed floating barrier – known as a containment boom — that can prevent disastrous consequences of marine oil spills within minutes of leak detection.

“Oil spills today still turn into major disasters because there are no immediate containment systems onsite. There is nothing onsite to keep oil from spreading. So when the oil spill response team arrives on the scene, it’s always too late,” cofounder Haim Greenberg tells ISRAEL21c. “We have a disruptive concept of immediate response because there is none today.”

Standard booms are too big to keep onboard major spill sources like large ships and oil rigs, and must be stored offshore. When an oil spill occurs, disaster crews need to make their way to the storage site, load the boom onto two ships, sail to the spill and deploy the barriers. This can take a day or more.

And the damage that ensues in the meantime can be extensive.

The 2010 Gulf of Mexico spill, in the wake of the Deepwater Horizon drilling rig explosion, took 87 days to contain. An estimated 3.19 million barrels of oil leaked into the waters.

HARBO’s T-fence Immediate Booming System is 15 to 20 times lighter than regular containment booms and can be preinstalled onboard large ships and rigs. It includes a compact vessel the size of a lifeboat.

“[We wanted it to be] very simple to operate and enable non-trained oil spill professionals to contain the spill in those first few hours when it is most critical,” Boaz Ur, HARBO’s cofounder and chief executive officer told the Ohmsett (New Jersey) Gazette. “In our product development work we found that this piece is critical, since professionals on ships, rigs or at oil terminals cannot be expected to operate complex emergency equipment. So we made it simple; push a button — just like a lifeboat.”

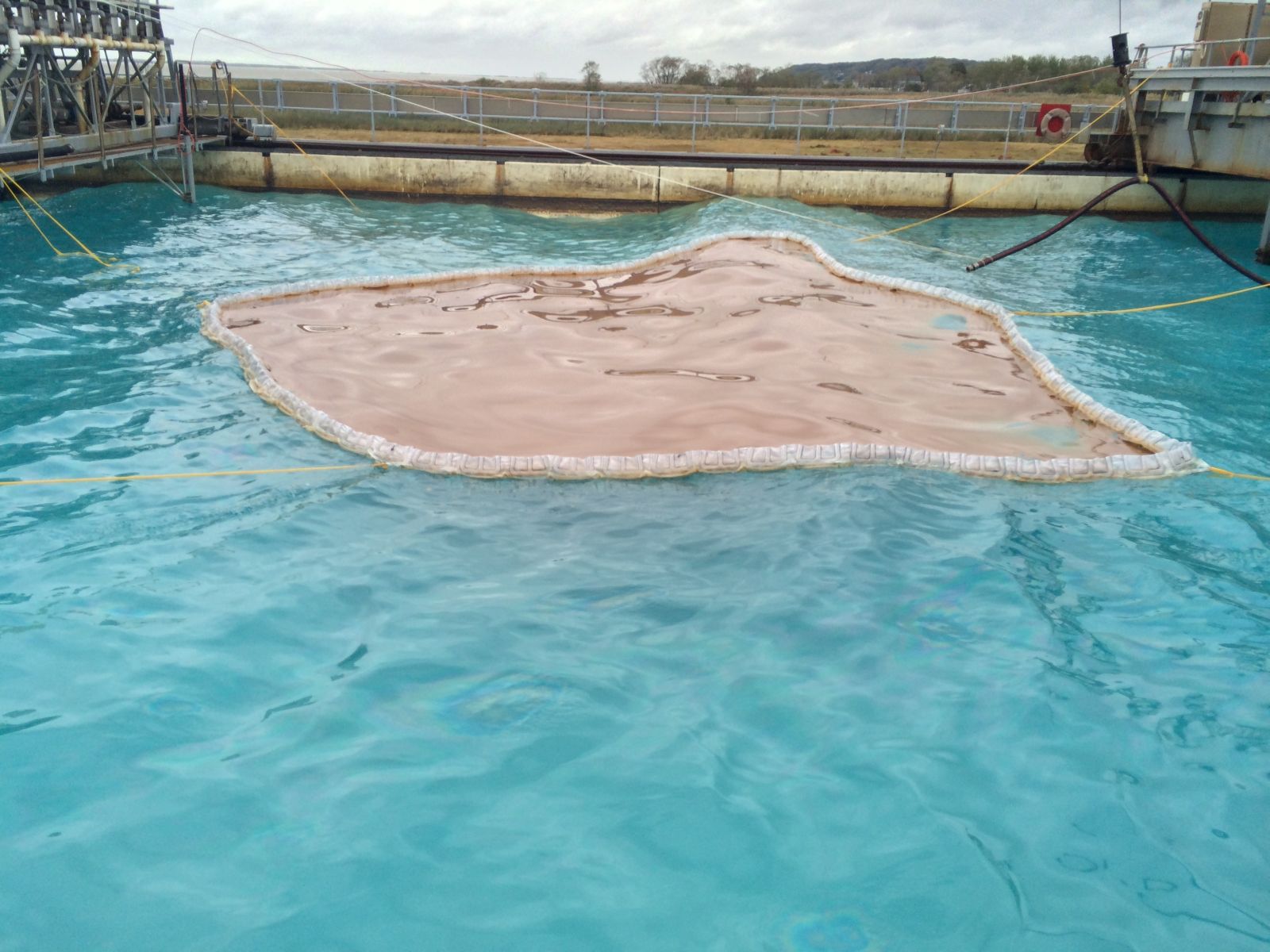

In October 2014, HARBO tested its product at the Ohmsett facility, the only one of its kind where full-scale oil-spill response equipment testing, research, and training can be conducted in a marine environment.

Other booms that arrive for testing usually come in shipping containers. HARBO’s 100-foot boom arrived in two suitcases and contained approximately two tons of oil with no losses.

From an idea to a game changer

CTO Arnon Shany, Greenberg and Ur had no special affinity for the world’s waterways before happening on the idea to revolutionize the field. (The company name is an acronym of their first names: Haim ARnon BOaz.)

Greenberg tells ISRAEL21c that he and Shany used to meet up just to talk about ideas. “Usually we talked about innovating ideas and we didn’t do anything about it. And then one day, Arnon came to me to talk about containing land oil spills immediately, like if a tractor hit a pipe. I said I think it will be better if we find something to contain oil spills at sea. And we began working from there.”

They went to talk to Nitai Drimer, a naval expert and an associate mechanical engineering professor at the Technion-Israel Institute of Technology. He gave them a green light.

“People have been trying for years to disrupt this field. There are dozens of patents that people registered but couldn’t make the product work. Everything that was tried failed,” says Greenberg. “After our first test we were told by a senior oil-spill expert that we were going to take industry by storm.”

Greenberg says the geometry of their boom is the secret behind their success.

The prefabricated modular booms are assembled and inflated with air and injected with seawater. The boom moves with the currents and waves and is not pushed off course.

“We went through dozens of prototypes, testing offshore in the Mediterranean with about four to six foot waves,” said Ur. “When we were certain that our boom’s capabilities exceeded our most optimistic expectations, we applied for international patents. Only then we were ready for Ohmsett.”

Officially established in 2013, HARBO won first prize in the University of California-Berkeley’s startup competition in the energy and clean-tech category the previous year.

Greenberg says the interest in his company’s system has been widespread among all potential spill sources, even from countries that have no trade agreements with Israel. Oil and gas operators, oil-spill response companies and investors have approached HARBO from countries including the United States, Canada, Nigeria, Brazil, Mexico, Saudi Arabia, Indonesia, Netherlands, Thailand, Angola and Singapore.

“HARBO succeeded to do what was considered almost impossible: to develop an immediate offshore containment boom, designed to be ready for deployment on board every potential point of failure,” said Ur. “We are now focused on the system implementation as well as working on the boom production lines.”

HARBO has a working model of its patented product but it’s not on the market just yet. HARBO will be launching a beta site in Holland in the next nine to 12 months and will start taking orders in the last quarter of 2016, says Greenberg.

For more information, click here.